Piling forms the foundation of both fixed jetties and piled pontoons, but the role piles play in each structure is fundamentally different. While fixed jetties rely on piles for permanent load transfer and structural stability, piled pontoons use piles mainly for guidance and lateral restraint.

Selecting the wrong piling method can increase construction cost by 20–30% or lead to long-term operational issues. This blog compares piling methods for fixed jetties and piled pontoons, helping engineers and developers choose the right approach for each application.

In fixed jetties, piles carry the full structural load — including deck weight, live loads, and vessel berthing forces — transferring them directly into the seabed. These piles are permanently embedded and designed for long service life.

In piled pontoons, piles do not carry vertical loads. Instead, floating pontoons slide along pile guides, allowing vertical movement with water levels while restricting horizontal drift. Here, piles primarily resist lateral forces from current, wind, and vessel interaction.

Fixed jetties demand piles with high load-bearing and bending resistance.

Common piling options include:

Steel Tubular Piles

Widely used for commercial and industrial jetties, steel tubular piles offer high axial and lateral capacity. They are suitable for deeper water and can support heavy loads exceeding 40–60 tonnes per pile, depending on diameter and soil conditions.

Reinforced Concrete Piles

Concrete piles are often used in moderate-load jetties and passenger terminals. They provide good durability and corrosion resistance, particularly in less aggressive marine environments, with design lives exceeding 40 years.

Bored Cast-in-Situ Piles

Used where vibration control is critical, bored piles minimize disturbance and are suitable for urban riverfronts. However, they may increase construction timelines by 15–20% compared to driven piles.

Piled pontoons require piles designed primarily for guidance and lateral restraint.

Typical piling options include:

Steel Guide Piles

Steel piles with smooth finishes are ideal for pontoon sleeves. They allow controlled vertical movement while limiting lateral displacement. Properly designed guide piles can reduce pontoon drift by 80–90%.

Sleeved Pile Systems

These incorporate low-friction sleeves or rollers mounted on the pontoon structure. This system reduces wear and extends pile life by 20–25%.

Driven vs. Bored Piles

Driven piles are generally preferred for piled pontoons due to faster installation and better alignment. Bored piles may be used in noise-sensitive zones but require precise tolerances to ensure smooth pontoon movement.

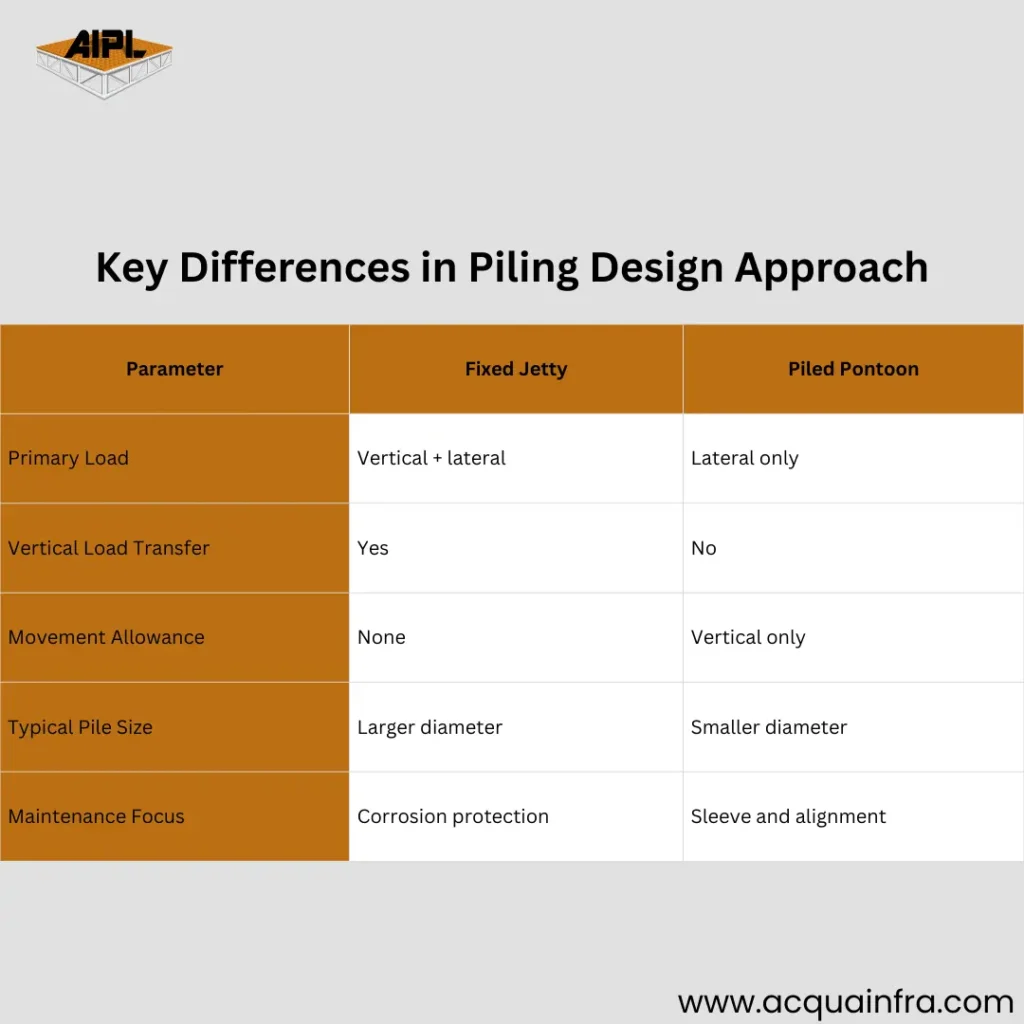

Key Differences in Piling Design Approach

Designing piles correctly for their intended function improves system efficiency and reduces long-term maintenance by 15–25%.

Piling method selection also impacts cost and environmental footprint.

Early geotechnical investigation helps optimize pile design and avoid overengineering.

Fixed jetty piles carry full structural loads, while piled pontoon piles mainly provide lateral guidance.

Piled pontoon piling is generally more economical due to smaller pile sizes and reduced material use.

Steel tubular piles are preferred for heavy-duty fixed jetties due to their high axial and lateral load capacity and suitability for deep-water conditions.

No. In piled pontoon systems, vertical loads are supported by buoyancy. Piles only guide movement and resist horizontal forces from wind, current, and vessel interaction.

Smooth-finished steel guide piles are most commonly used, allowing controlled vertical movement while restricting lateral drift.

Properly designed guide piles can reduce lateral pontoon drift by 80–90%, significantly improving safety and operational stability.

Sleeved pile systems use low-friction sleeves or rollers attached to the pontoon, enabling smooth vertical movement and reducing pile wear by 20–25%.

Yes. Piled pontoon systems usually require 25–35% less steel and concrete, making them more economical for many applications.

Piled pontoons cause significantly less seabed disturbance than fully fixed structures, making them more suitable for environmentally sensitive water bodies.

Yes. Piled pontoons can accommodate vertical water-level changes naturally, while fixed jetties require complex design allowances for tidal or seasonal variations.

The best piling method depends entirely on whether the structure is a fixed jetty or a piled pontoon. Fixed jetties demand high-capacity piles designed for permanent load transfer, while piled pontoons require guide piles optimized for stability and movement control.

Understanding these differences ensures safer designs, better cost control, and long-term operational reliability.

Planning a fixed jetty or a piled pontoon system?

Partner with Acquafront Infrastructure Pvt. Ltd. (AIPL) for expert piling design, engineered pontoon systems, and proven marine infrastructure solutions.

👉 Contact our team to select the right piling strategy for your project.

About the Author

Mr. Achin Agrawal, Director & CTO.