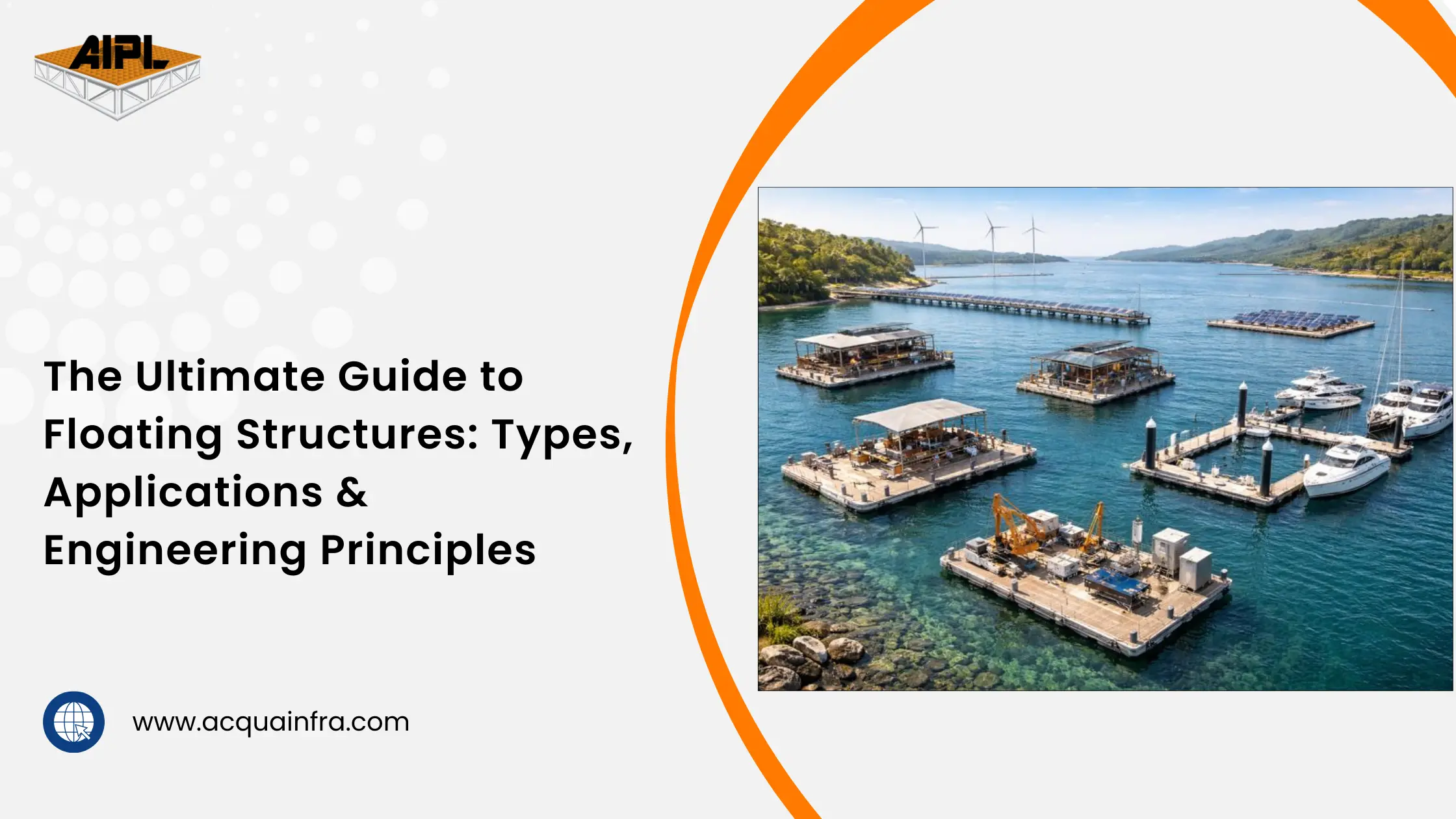

Floating structures are no longer niche solutions limited to marinas or temporary platforms. From ports and inland waterways to defence, tourism, and smart waterfronts, floating structures are shaping the future of marine infrastructure.

As someone who has worked closely with waterfront and marine projects, I’ve seen how floating solutions often solve problems that fixed structures simply can’t—especially where water levels, soil conditions, or environmental sensitivity are major concerns.This guide breaks down Ultimate Guide to Floating Structures floating structures in a simple, practical, and decision-friendly way.

Floating structures are engineered platforms designed to remain buoyant on water, supported by flotation units instead of fixed foundations. They are anchored or moored to maintain position while adapting naturally to water-level changes.

Environment-friendly construction

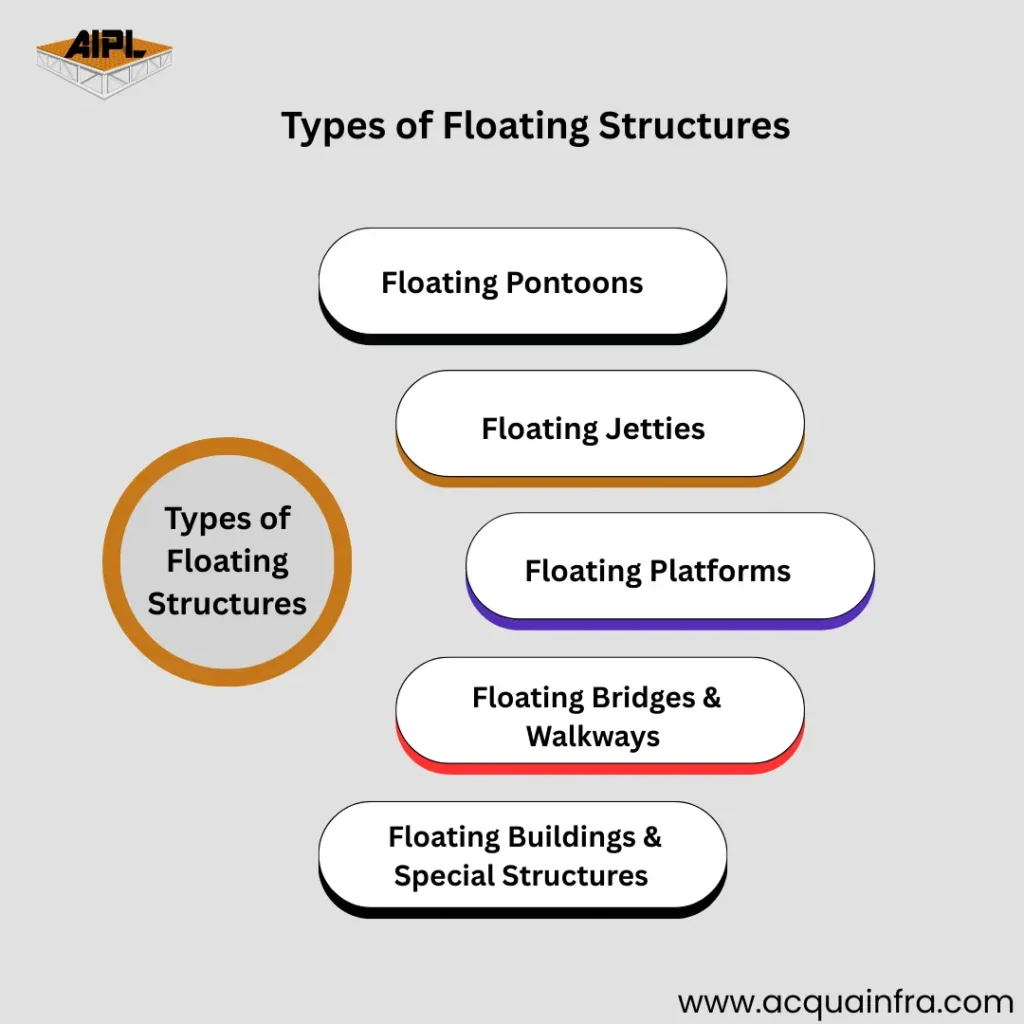

Types of Floating Structures

1. Floating Pontoons

Most common type, used for docks, jetties, and walkways.

Real-life use:

Marinas in Goa and Kerala use modular floating pontoons to accommodate yachts and leisure boats during seasonal water-level changes.

Designed for passenger ferries, patrol boats, and cargo handling.

Real-life use:

Inland water terminals on the Ganga use floating jetties for year-round ferry operations without rebuilding after floods.

Heavy-duty platforms for industrial, defence, or offshore activities.

Real-life use:

Oil & gas maintenance platforms and floating work barges used for piling and dredging operations.

Pedestrian or light-vehicle connectivity over water bodies.

Real-life use:

Floating walkways at tourist destinations and eco-parks where permanent bridges are restricted.

Includes floating restaurants, event decks, and research stations.Real-life use:

Floating cafes and tourism pontoons in backwater regions with strict land-use restrictions.

Structures are designed using Archimedes’ principle, ensuring adequate freeboard even under maximum live load.

Proper centre of gravity and pontoon spacing prevent tilting and excessive movement.

Chains, piles, or shore anchors ensure controlled movement without drift.

Materials are selected to resist:

Designed as per IS codes, PIANC guidelines, and port authority norms.

At AIPL, we don’t just supply floating structures—we engineer solutions.

Our expertise includes:

Whether it’s a passenger jetty, marina dock, or industrial platform, AIPL ensures performance, safety, and longevity.

Floating structures offer flexibility, sustainability, and engineering efficiency where traditional construction struggles. With the right design and execution, they become long-term assets—not temporary fixes.

Frequently Asked Questions

Typically 25–40 years, depending on material and maintenance.

Yes, they rise with water levels when properly moored.

Yes, industrial-grade platforms are designed for high loads.

Not always—many use anchoring or chain mooring systems.

They have minimal seabed disturbance compared to fixed structures.

HDPE pontoons, concrete floats, steel frames, aluminium decking.

Periodic inspection, cleaning, and hardware replacement.

Yes, depending on location and usage.

Yes, when engineered for static and dynamic loads.

Through pontoon design, damping systems, and flexible mooring.

Often cheaper than piling in deep or soft seabeds.

Planning a floating jetty, pontoon, or marine platform?

Connect with AIPL today to design floating structures that adapt, endure, and perform—no matter the water conditions.