With the rising city population and the increasing environmental challenges, effective sanitation is now more essential than ever. Traditional wastewater treatment systems require large infrastructure and a lot of terrain, which is an issue in areas with high populations or regions prone to flooding. Floating platforms provide an environmentally sustainable and sustainable option for issues related to the treatment of sewage, while also protecting the water resources.

These systems are floating units made to treat and clean wastewater directly on the water bodies. These platforms use advanced techniques for filtration and biological treatment, as well as alternative power sources to ensure sustainable and efficient treatment of wastewater.

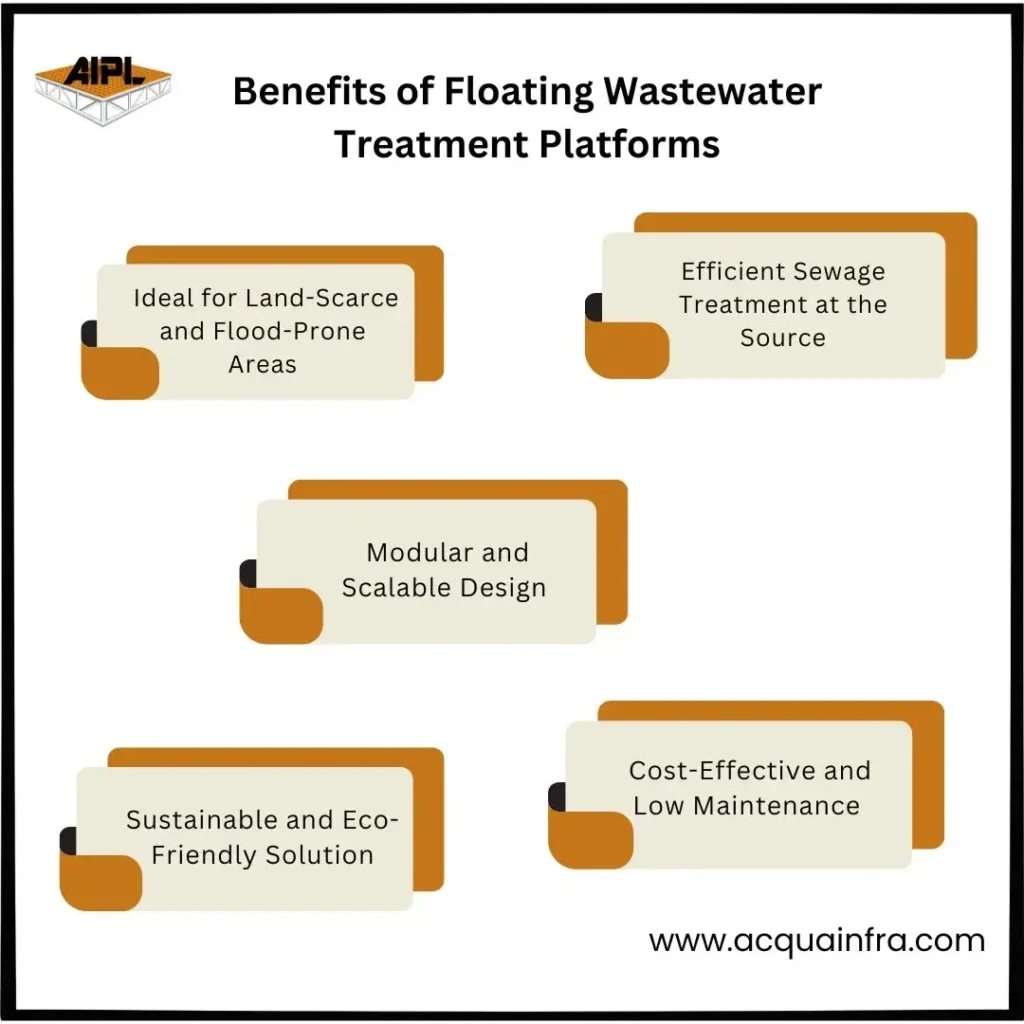

Key Benefits of Floating Wastewater Treatment Platforms

1. Ideal for Land-Scarce and Flood-Prone Areas

Traditional treatment services need huge spaces, while floating platforms work on water bodies, which is why they are ideal for coastal and urban areas.

2. Efficient Sewage Treatment at the Source

Floating platforms are typically situated near lakes, rivers or release areas to keep untreated wastewater from contaminating lakes, rivers and waterbodies in various ways.

3. Modular and Scalable Design

The platform can be modified and expanded to meet the growing needs in wastewater treatment. It can be utilised in small towns as well as larger cities.

4. Sustainable and Eco-Friendly Solution

A large portion of floating treatment units are made up of solar panels and high-efficiency filters that reduce their carbon footprint. They also assist in the rehabilitation of ecosystems within the water by getting rid of the garbage prior to getting into the natural sources.

5. Cost-Effective and Low Maintenance

When compared to the traditional treatment of wastewater, floating platforms require less infrastructure investment and aren't vulnerable to frequent maintenance, which makes them an economically viable option for flood-prone or developing areas.

Primary Treatment removes large particles from waste. Bio-treatment utilises microorganisms and bacteria to remove the organic matter that gets disposed of. Advanced Filtration Membranes are used as chemical processes for purifying water. Disease the water treated is ecologically safe prior to being released to be reused or released.

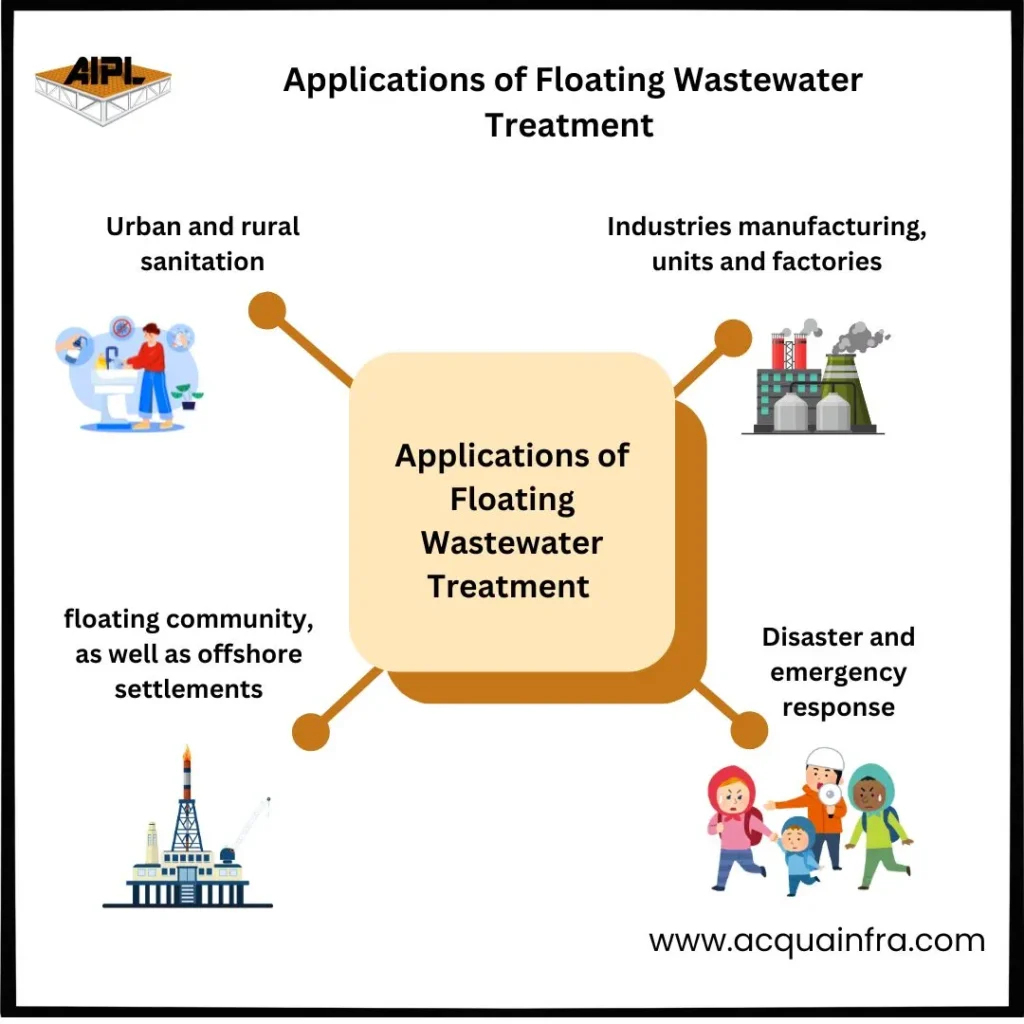

Key Applications of Floating Wastewater Treatment Platforms

Urban and rural sanitation.

Industries manufacturing, units and factories.

floating community, as well as offshore settlements.

Disaster and emergency response.

Managing wastewater efficiently is crucial for urban sustainability. Acqua Infra Pvt. Ltd. (AIPL) provides innovative floating platform solutions designed to enhance wastewater treatment and sewage management. These modular, cost-effective, and eco-friendly platforms ensure efficient water purification while utilizing minimal land space.

Conclusion

Treatment facilities for water that float are a revolution in the landscape of management for water and offer a solid, durable, versatile, flexible, and affordable solution to industrial and urban water issues.

Are you seeking to learn about new strategies for managing water? Visit Acqua Infra today!

A Floating Pump Pontoon is a modular floating platform designed to support pumps and associated equipment on water bodies. It provides stable, safe, and accessible infrastructure for water pumping applications in rivers, reservoirs, lakes, and industrial water sources.

Floating Pump Pontoons eliminate the need for heavy civil construction and land acquisition, which often delay projects and harm the environment. They ensure uninterrupted water access even during summer low levels or flood peaks, where fixed pump houses fail. Their modular and mobile nature provides flexibility for relocation or capacity expansion, while reducing downtime, accelerating project timelines, and cutting both capital and maintenance costs.

Urban & Rural Water Supply Projects, Irrigation Systems, Industrial Cooling Water Supply, Mining & Dredging Operations, Power Plant Intake Systems, Flood Management & Disaster Relief.

Public Health Engineering Departments, Power & Energy Utilities, Irrigation & Agriculture, Oil & Gas / Petrochemicals, Mining & Heavy Industry.

Steel (certified) is the primary material for structural components. Other components combine with HDPE or composite elements for buoyancy/support depending on load and site conditions.

Pumps are mounted on vibration-resistant skids with integrated piping, flexible couplings, and access platforms. The pontoons are engineered to handle static and dynamic loads.

The pontoon system rises and falls with water levels, ensuring uninterrupted pump operation and maintaining constant suction conditions.

Yes. The modular design allows pontoons to be transported in parts by road and assembled at the project site, making them ideal for remote and logistically challenging environments.

Small systems (up to 500 m³/hr): 2–3 months; Medium systems (500–2000 m³/hr): 3–6 months; Large systems (2000+ m³/hr): 6–9 months.

Bathymetric & Topographic Survey Data, Seasonal Water Level Variation Data, Pump Capacity & Type, Load & Utility Requirements, Site Accessibility & Deployment Constraints.

Yes. They are designed with redundancy in buoyancy, anchoring systems, and stability margins to withstand wind, waves, and current loads. Compliance with Indian Standards is ensured.

Anchoring solutions include mooring chains, piles, and deadweight anchors depending on depth, current, and soil strata.

Regular inspection of pontoons, coatings, anchoring systems, pump alignment, and preventive maintenance of pipelines and valves.

Yes. AMC covers structural inspections, preventive maintenance, and on-call support to ensure continuous and safe pumping operations.

Steel Modular Pontoons: 20–25 years with periodic maintenance; HDPE Floating Cubes: 10–15 years for light/temporary use cases.

All types of pumps including Vertical turbine, Centrifugal, Submersible, and Engine-driven pumps can be installed.

Yes. AIPL provides rental solutions for temporary or emergency requirements such as flood relief, mining dewatering, or irrigation needs.

Adaptability, Cost Efficiency, Faster Deployment, Low Downtime, Versatility, Scalability, and Safe Accessibility for operators.