A Growing Threat, A Smarter Solution

Floods are no longer unusual; they are seasonal, often monthly, and always expensive. As a digital marketer of pioneering infrastructure brands, I've witnessed how floating platforms are silently redefining survival in flood-risk zones—not as rescue interventions, but as daily infrastructure.

No matter whether it's housing, sanitation, or water pumping, the answer doesn't always reside on land—sometimes it floats.

Climate change has resulted in uncertain weather conditions and increased monsoons.

Urbanization and deforestation have broken up natural water absorption.

Aging infrastructure in most regions can't cope with today's rainfall or runoff.

The World Bank reports that more than 1.5 billion people reside in flood-risk areas—and that figure is growing.

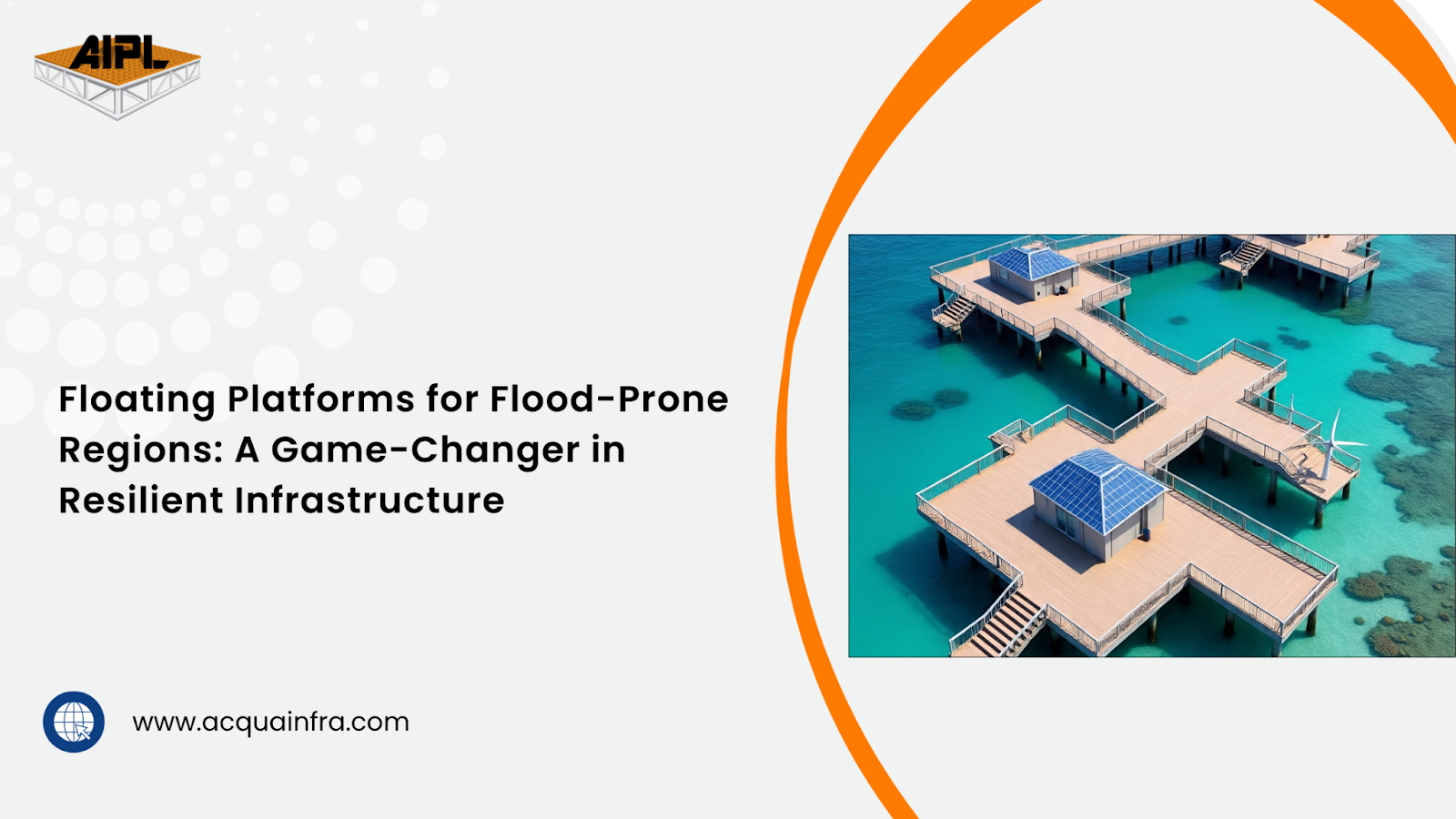

Unlike permanent structures, floating platforms adapt to water levels to avoid submergence or collapse.

For emergency shelters or medical facilities, water pumps, or other purposes, these platforms are modular and portable, providing speedy setup in emergencies.

Constructed from buoyant and corrosion-resistant materials such as Mild steel, HDPE or aluminum, floating platforms do not disrupt ecosystems or need massive land excavation.

They can accommodate:

Floating houses

Emergency medical or rescue facilities

Solar-powered water treatment

Floating pump systems

Not limited to emergencies—these systems can be left in position for months or even years, offering stable solutions in perpetually impacted areas.

Bangladesh: Floating schools and libraries keep education continuous throughout the year in floodplains.

India (Assam, Kerala): Floating bridges and pump pontoons used during monsoon flooding.

Netherlands: Floating neighborhoods constructed as permanent solutions to sea level rise.

Personal Insight: I discovered while doing research on this project a floating village in Cambodia that has homes, schools, and markets adjust with the water. It's not only practical—it's optimistic.

AIPL (Advanced Infrastructure Projects Ltd.) invented floating pump pontoons tailored to meet one of the most urgent issues during floods: the availability of clean, flowing water.

Stability under fluctuating water levels

Long-lasting, anti-corrosive construction materials

Rapid, site-assembled assembly

Low maintenance

Industrial, agricultural, and municipal custom sizes

Industry Tip: Submerged fixed pump stations perish. AIPL's pontoons ride above peril, providing continuous water supply even with loss of ground-level access.

Floating platforms support multiple UN Sustainable Development Goals (SDGs):

Clean Water & Sanitation (Goal 6)

Sustainable Cities (Goal 11)

Climate Action (Goal 13)

They're not only reactive—

they're proactive, adaptive, and green.

An inflatable, module-based building built to float structures like buildings, pumps, or utilities above water, best suited in aquatic or flood-prone areas.

Acquafront Infrastructure Pvt. Ltd. delivers adaptive floating infrastructure solutions for flood-prone and water-logged regions, supporting resilient housing, access pathways, and essential service platforms.

Yes. With a good design and anchoring, they can last for decades as homes, pump stations, or public facilities.

It floats and stabilizes a water pump, enabling water to be pumped efficiently even at fluctuating levels of water or during floods.

Although they are more expensive than conventional structures to implement initially, the cost savings on maintenance, disaster relief, and adaptability in the long term make them inexpensive.

AIPL employs tailored engineering, industrial-grade materials, and a modularity concept, which enables their solutions to be scalable, resilient, and easy to roll out.

Steel (certified) is the primary material for structural components. Other components combine with HDPE or composite elements for buoyancy/support depending on load and site conditions.

Pumps are mounted on vibration-resistant skids with integrated piping, flexible couplings, and access platforms. The pontoons are engineered to handle static and dynamic loads.

The pontoon system rises and falls with water levels, ensuring uninterrupted pump operation and maintaining constant suction conditions.

Yes. The modular design allows pontoons to be transported in parts by road and assembled at the project site, making them ideal for remote and logistically challenging environments.

Small systems (up to 500 m³/hr): 2–3 months; Medium systems (500–2000 m³/hr): 3–6 months; Large systems (2000+ m³/hr): 6–9 months.

Yes. They are designed with redundancy in buoyancy, anchoring systems, and stability margins to withstand wind, waves, and current loads. Compliance with Indian Standards is ensured.

Anchoring solutions include mooring chains, piles, and deadweight anchors depending on depth, current, and soil strata.

Regular inspection of pontoons, coatings, anchoring systems, pump alignment, and preventive maintenance of pipelines and valves.

Yes. AMC covers structural inspections, preventive maintenance, and on-call support to ensure continuous and safe pumping operations.

Steel Modular Pontoons: 20–25 years with periodic maintenance; HDPE Floating Cubes: 10–15 years for light/temporary use cases.

All types of pumps including Vertical turbine, Centrifugal, Submersible, and Engine-driven pumps can be installed.

Yes. AIPL provides rental solutions for temporary or emergency requirements such as flood relief, mining dewatering, or irrigation needs.

Adaptability, Cost Efficiency, Faster Deployment, Low Downtime, Versatility, Scalability, and Safe Accessibility for operators.

Let’s Build Smarter for High-Water Zones.

If you’re planning infrastructure in flood-prone areas, don’t wait for disaster. Start building resiliently—with floating solutions.

👉 Let's Connect! Reach out for consultations, collaborations, or customized floating solutions for your next big idea.