In marine terminals, fixed jetties are the backbone of operations. They support cargo handling, passenger movement, and vessel berthing every single day. However, constant exposure to saltwater, tides, waves, heavy loads, and changing weather conditions causes gradual deterioration of concrete and steel elements.

👉 Ignoring early signs of damage in marine structures often leads to higher repair costs and operational downtime later.

This is why timely fixed jetty refurbishment and concrete repair is not just maintenance—it’s a strategic investment.

What Is a Fixed Jetty?

A fixed jetty is a permanently constructed marine structure supported by piles driven into the seabed. Unlike floating jetties, fixed jetties remain stationary and are commonly used in:

These structures are usually made of reinforced concrete, steel piles, or a combination of both.

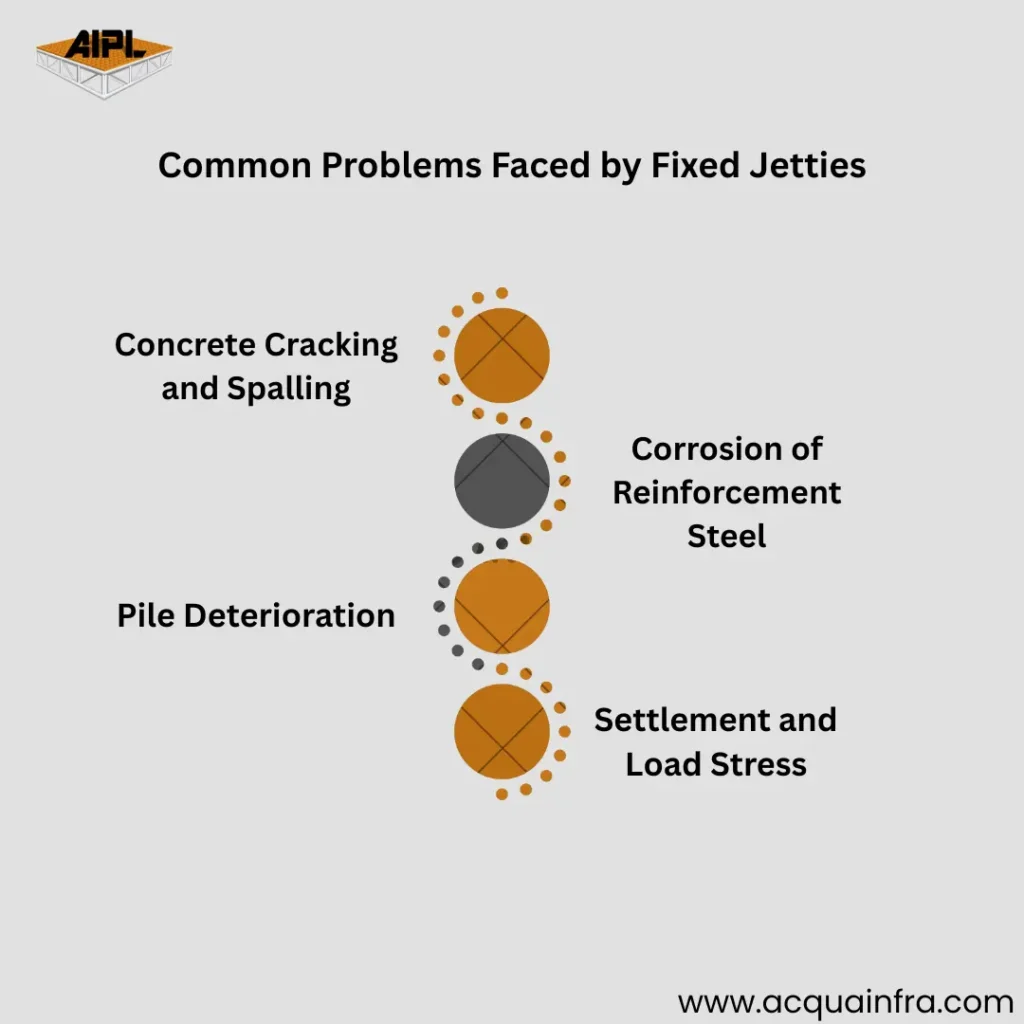

Over time, marine environments accelerate structural damage. Some of the most common issues include:

Saltwater penetrates concrete, corroding internal reinforcement and causing cracks or surface breakage.

Chlorides from seawater trigger rusting, leading to loss of structural strength.

Piles suffer from marine growth, abrasion, and chemical attack at splash and tidal zones.

Increased operational loads or vessel impact can weaken jetty decks and beams.

Delaying refurbishment can result in:

A well-planned refurbishment program extends the life of the jetty by decades.

This involves encasing damaged piles or columns with new reinforced concrete to restore strength and durability.

Benefits:

A highly effective corrosion control method that prevents steel reinforcement from rusting.

Types:

This technique is especially useful for long-term corrosion prevention.

Fine cracks are sealed using epoxy resins, restoring structural integrity and preventing water ingress.

Best for:

Special marine-grade mortars are used to repair spalled or damaged concrete surfaces.

Advantages:

Marine-grade coatings protect concrete and steel from aggressive environmental exposure.

Common applications:

In cases of increased operational demand, techniques like FRP wrapping or additional reinforcement are used.

Step-by-Step Fixed Jetty Refurbishment Process

A structured approach ensures minimum disruption to terminal operations.

Acquafront Infrastructure Pvt. Ltd. (AIPL) brings deep expertise in marine and waterfront infrastructure projects across India.

AIPL’s Key Strengths:

From small-scale repairs to large jetty rehabilitation projects, AIPL focuses on durability, safety, and long-term performance.

Benefits of Choosing Professional Marine Repair Solutions

Enhanced operational efficiency

In practice, fixed jetty refurbishment follows proven maintenance methodologies that have been successfully applied across Indian and global marine terminals:

Conclusion

Fixed jetty refurbishment and concrete repair are essential to ensure the safety, durability, and uninterrupted operation of marine terminals. With the right inspection methods, repair techniques, and marine-grade materials, aging jetty structures can be restored to perform reliably for decades. Partnering with experienced marine infrastructure specialists like AIPL ensures that refurbishment work is not only technically sound but also designed for long-term performance in demanding marine conditions.

Fixed jetty refurbishment is the process of repairing, strengthening, and protecting an existing jetty structure to restore its safety, load-bearing capacity, and durability. It includes concrete repairs, corrosion protection, pile strengthening, and surface treatments to extend the jetty’s service life.

Marine concrete is continuously exposed to saltwater, chlorides, moisture, tides, and wave action. These elements penetrate concrete, causing reinforcement corrosion, cracking, and spalling, which accelerates deterioration compared to inland structures.

There is no single solution. The best repair method depends on the extent of damage, location (splash, tidal, or submerged zone), and operational requirements. Techniques like concrete jacketing, epoxy injection, cathodic protection, and protective coatings are often combined.

Acquafront Infrastructure Pvt. Ltd. offers inspection, maintenance, and lifecycle support services for floating infrastructure systems to improve long-term performance, safety, and operational efficiency by 60%.

Concrete jacketing involves encasing damaged piles or columns with new reinforced concrete. This method improves structural strength, protects against corrosion, and is widely used for marine piles exposed to tidal and splash zones.

Cathodic protection prevents corrosion by controlling the electrochemical reaction that causes steel to rust. It uses sacrificial anodes or impressed current systems to protect reinforcement steel inside concrete from chloride attack.

The duration depends on the extent of damage, repair methods, and site conditions. Small repairs may take a few weeks, while large refurbishment projects can extend over several months.

If your fixed jetty or marine terminal is showing signs of deterioration, now is the right time to act. Early refurbishment can save significant costs and prevent operational disruptions. Connect with AIPL today to get a professional assessment and reliable marine repair solutions tailored to Indian coastal and riverine conditions. Build stronger, safer, and longer-lasting waterfront infrastructure with confidence.