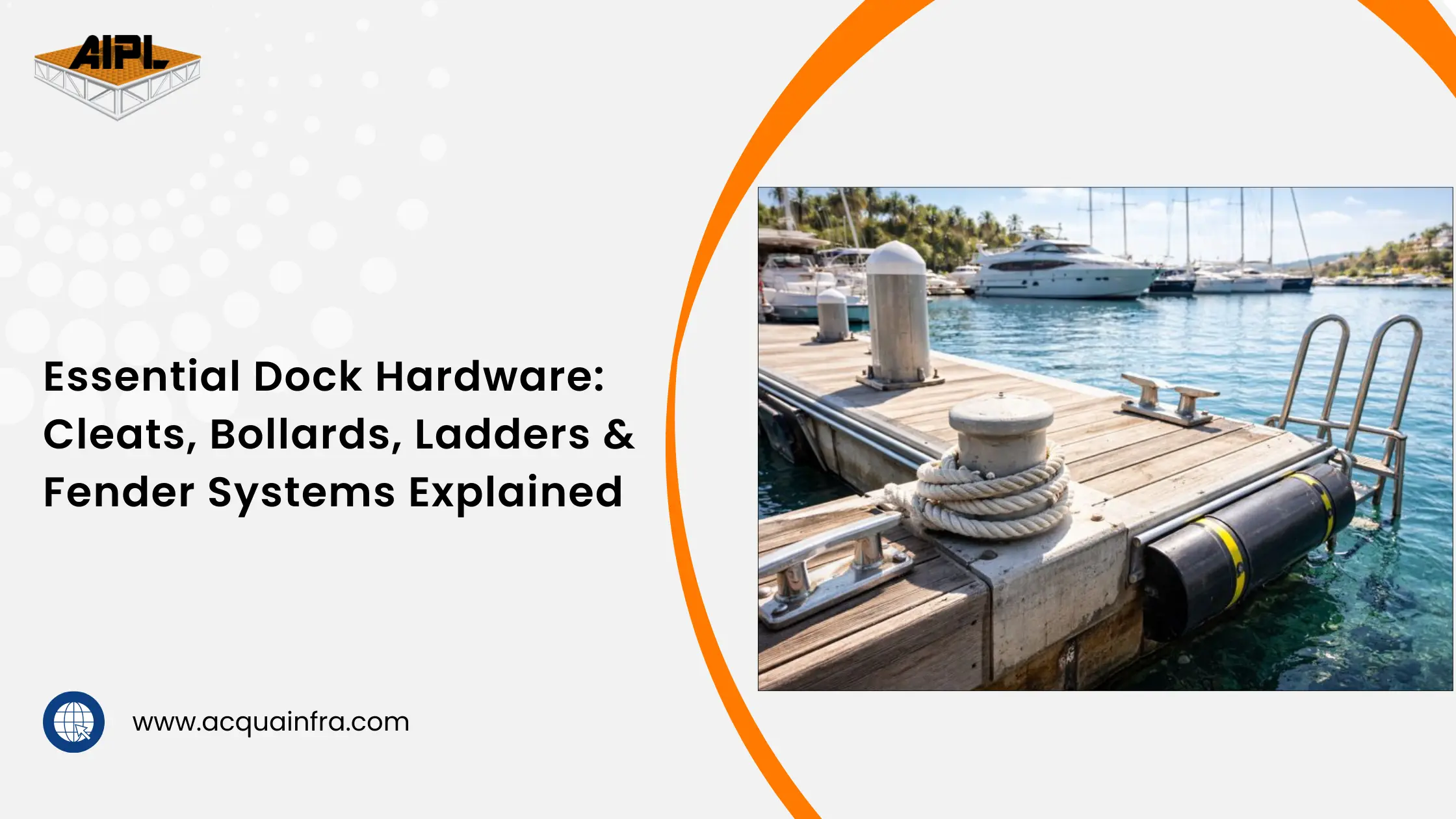

As working closely with infrastructure and marine clients, I’ve learned one thing very clearly: a dock is only as strong, safe, and reliable as the hardware installed on it. While floating pontoons or fixed jetties often get the spotlight, it’s the supporting dock hardware that silently ensures smooth operations every single day.

This detailed guide explains the most essential dock hardware components—cleats, bollards, ladders, and fender systems—in simple language, with practical insights drawn from real marine operations.

Why Dock Hardware Matters More Than You Think

Dock hardware plays a critical role in:

- Vessel safety during berthing

- Load management and mooring strength

- Crew and passenger access

- Protecting structures from impact damage

Whether it’s a commercial port, marina, river jetty, or industrial terminal, the right hardware selection reduces long-term maintenance costs and improves operational efficiency.

1. Dock Cleats: Securing Vessels Safely

Dock cleats are used to tie vessels securely to the dock using ropes or mooring lines.

Common Types of Dock Cleats

- Horn Cleats – Most commonly used in small to mid-size docks

- T-Cleats – Suitable for higher load capacities

- Cam Cleats – Used in light-duty and marina applications

Materials Used

- Cast iron

- Stainless steel

- Ductile iron

- Marine-grade aluminum

Where They Are Used

- Floating docks

- Marina pontoons

- Small cargo and service jetties

Personal Insight: In many Indian riverfront projects, incorrectly sized cleats lead to rope slippage and accelerated wear. Proper load calculation is essential.

2. Bollards: Heavy-Duty Mooring Solutions

Bollards are robust mooring fixtures designed for large vessels and high-load environments.

Types of Bollards

- Single Bitt Bollards

- Double Bitt Bollards

- Tee-Head Bollards

- Horn Bollards

Load Capacity

Ranges from 500 Kg to over 200 tons depending on design and foundation.

Applications

- Commercial ports

- Naval docks

- LNG terminals

- Industrial jetties

Real-World Use: Indian major ports like Kandla and Paradip rely on high-capacity bollards to manage tidal variations and vessel movement safely.

3. Dock Ladders: Ensuring Safe Access

Dock ladders provide safe vertical access between dock decks and water levels.

Common Ladder Types

- Fixed vertical ladders

- Angled safety ladders

- Retractable dock ladders

Key Features

- Anti-slip rungs

- Corrosion-resistant coating

- Rounded safety handholds

Materials

- FRP (Fiber Reinforced Plastic)

- Galvanized steel

- Stainless steel

Human Touch: A well-placed ladder can be life-saving during emergencies. Many modern projects now include ladders as a mandatory safety feature.

4. Fender Systems: Protecting Docks and Vessels

Fender systems absorb impact energy during berthing, preventing structural damage.

Types of Fender Systems

- Rubber fenders

- Cone fenders

- Arch fenders

- Cylindrical fenders

- Composite and foam-filled fenders

Selection Factors

- Vessel size

- Berthing velocity

- Tidal variation

- Dock structure type

Applications

- Container terminals

- Passenger jetties

- Floating docks

- Industrial marine terminals

Maintenance Tip: Regular inspection of fenders helps avoid costly structural repairs.

Practical Real-Life Usage Examples of Dock Hardware

- Cleats at Marina Docks: In recreational marinas, cleats are installed at regular intervals on floating pontoons so boat owners can quickly secure vessels during daily docking and changing water levels.

- Bollards at Commercial Ports: At container and bulk cargo terminals, high-capacity bollards are used to safely moor large vessels during loading and unloading, especially under strong tidal currents and wind forces.

- Ladders on River Jetties: On riverine passenger jetties, fixed or FRP ladders are installed to allow safe boarding, emergency exit, and rescue access during fluctuating water levels.

- Fender Systems at Industrial Jetties: Rubber and cone fender systems are placed along fixed jetties to absorb berthing impact from cargo ships, preventing structural damage to both vessels and dock edges.

- Floating Dock Applications: On floating docks, flexible hardware fittings are used so cleats and fenders move with the platform, ensuring consistent vessel alignment and safety.

How AIPL Can Assist in Essential Dock Hardware Solutions

Acquafront Infrastructure Pvt. Ltd. (AIPL) brings hands-on expertise in designing, supplying, and installing dock hardware tailored to Indian marine conditions.

AIPL supports clients with:

- Site-specific hardware selection

- Load calculations and compliance support

- Corrosion-resistant materials

- Integration with floating and fixed dock systems

- Long-term maintenance guidance

From small river jetties to large commercial terminals, AIPL ensures safety, durability, and performance.

Conclusion

Dock hardware may appear secondary, but it directly impacts safety, durability, and operational success. Investing in the right components ensures smoother marine operations and long-term reliability.

Frequently Asked Questions

What is the difference between cleats and bollards?

Cleats are for smaller vessels, while bollards handle heavy-duty mooring loads.

Which dock hardware is mandatory for safety?

Ladders and fender systems are critical safety components.

How do I choose the right bollard capacity?

Based on vessel size, mooring load, and tidal conditions.

Are stainless steel cleats better than cast iron?

Yes, for corrosion resistance, especially in marine environments.

How often should dock hardware be inspected?

At least once every six months or after heavy vessel impact.

What materials are best for dock ladders?

FRP and stainless steel are preferred for durability.

What causes dock hardware failure?

Corrosion, overload, and poor installation.

What is the lifespan of marine-grade hardware?

Typically 15–25 years with proper maintenance.

How does tidal variation affect hardware choice?

Higher tidal variation requires flexible and stronger systems.

Looking to design or upgrade your dock hardware system? Connect with AIPL today for expert guidance, custom solutions, and reliable marine infrastructure support tailored to your project needs.

About the Author

Mr. Achin Agrawal, Director & CTO.

- Expertise includes R&D, Product development, Project design & engineering.

- National Meritorious Innovation Award 2018 by NRDC (A DST Enterprise) presented during Innovate India conference 2019 at EDII, Ahmedabad.

- Recognised for groundbreaking innovation with patent no. 485553 in marine Industry.