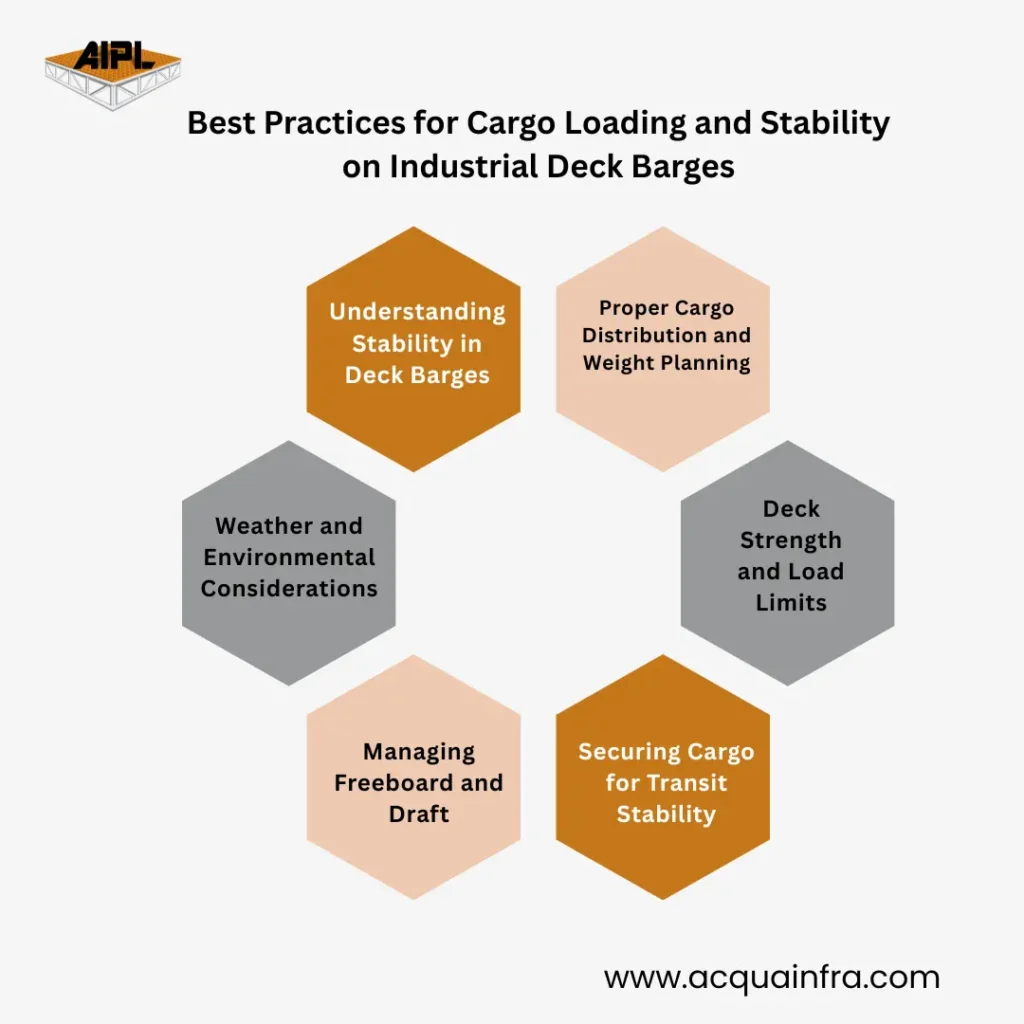

Industrial deck barges play a critical role in transporting heavy cargo, construction equipment, and oversized modules across rivers, reservoirs, and coastal waters. However, improper cargo loading can lead to serious risks — including instability, excessive trim, structural stress, and in extreme cases, capsizing.

Studies in marine operations show that over 60% of barge-related incidents are linked to improper load distribution or stability miscalculations. This makes it essential for operators and engineers to follow proven best practices that ensure safety, efficiency, and regulatory compliance during barge operations.

Barge stability depends on how weight is distributed across the deck and how the vessel reacts to external forces such as currents, wind, and wave action. Unlike ships, industrial deck barges usually have a flat bottom and wide beam, which provides high initial stability — but only when cargo is placed correctly.

Poor loading can cause:

Maintaining stability is especially critical when handling heavy-lift cargo, cranes, or modular structures.

Balanced cargo distribution is the foundation of safe barge operations. Loads should always be spread evenly across the barge deck to maintain the center of gravity within safe limits.

Best practices include:

Well-planned load distribution can reduce stability-related risks by 30–40%, especially during towing or maneuvering.

Every industrial deck barge is designed for a specific deck load capacity, typically measured in tons per square meter. Exceeding this limit can lead to deck deformation or structural damage.

Key considerations:

Adhering to deck load ratings can extend barge service life by 20–25% and significantly reduce repair costs.

Even with correct placement, unsecured cargo can shift during movement, leading to sudden loss of stability.

Effective securing methods include:

Proper cargo securing can reduce transit-related incidents by up to 50%, particularly during long-distance towing or rough water conditions.

Freeboard — the vertical distance between the deck and waterline — is a critical safety parameter. Reduced freeboard increases the risk of water ingress, especially during wave action.

Operational best practices:

Maintaining adequate freeboard improves operational safety and ensures 25–30% better performance in moderate wave conditions.

Environmental forces directly impact barge stability. Wind loads, current velocity, and wave height must be factored into cargo planning.

For example:

Planning operations around weather forecasts can reduce operational delays by 15–20% and significantly improve safety margins.

Stability is not a one-time calculation — it must be monitored continuously throughout loading and transit.

Recommended practices:

Regular inspection helps detect early imbalance issues and can prevent over 70% of avoidable operational failures.

Proper cargo loading ensures stability, prevents excessive trim or heel, reduces structural stress, and minimizes the risk of capsizing during operations.

Uneven load distribution, overloading the deck, unsecured cargo, and ignoring environmental forces like wind and current are the main causes.

Balanced load distribution keeps the center of gravity within safe limits, reducing the risk of excessive draft, heel, or loss of freeboard.

Heavy cargo should be placed near the barge’s centerline and evenly distributed longitudinally to maintain optimal stability.

Exceeding deck load limits can cause deck deformation, structural damage, increased maintenance costs, and safety hazards.

Point loads should be spread using steel plates or load-spreading mats to prevent localized deck stress.

Common methods include welding supports, bolting frames, using chain lashings, stoppers, and temporary guide structures.

Draft is monitored visually and through measurements at marked draft points throughout the loading process.

Wind, waves, and currents increase dynamic forces that affect stability, especially when carrying tall or heavy cargo.

Safe and efficient cargo loading on industrial deck barges is a combination of engineering discipline, operational planning, and continuous monitoring. By following structured load distribution, respecting deck limits, securing cargo properly, and accounting for environmental conditions, operators can significantly enhance barge stability and operational reliability.

Planning cargo transport or marine construction using industrial deck barges?

Partner with Acquafront Infrastructure Pvt. Ltd. for engineered barge platforms designed for safe loading, superior stability, and long-term performance.

👉 Contact our team today to discuss the right deck barge solution for your project.