As water is critical and the need for sustainable and efficient management increases, infrastructural innovation becomes unavoidable. Floating pumping stations are a groundbreaking solution that solves the problem of many critical issues associated with traditional water management systems. These systems are adjustable, sustainable, and economical which makes them suitable for industry, municipalities and agricultural requirements.

In this blog, we will understand what floating pumping stations are, their advantages and applications, key attributes and how they function. We will also justify why Acquafront Infrastructure is a reliable partner for the realization of the technological solutions, some issues and the great prospects of the technology.

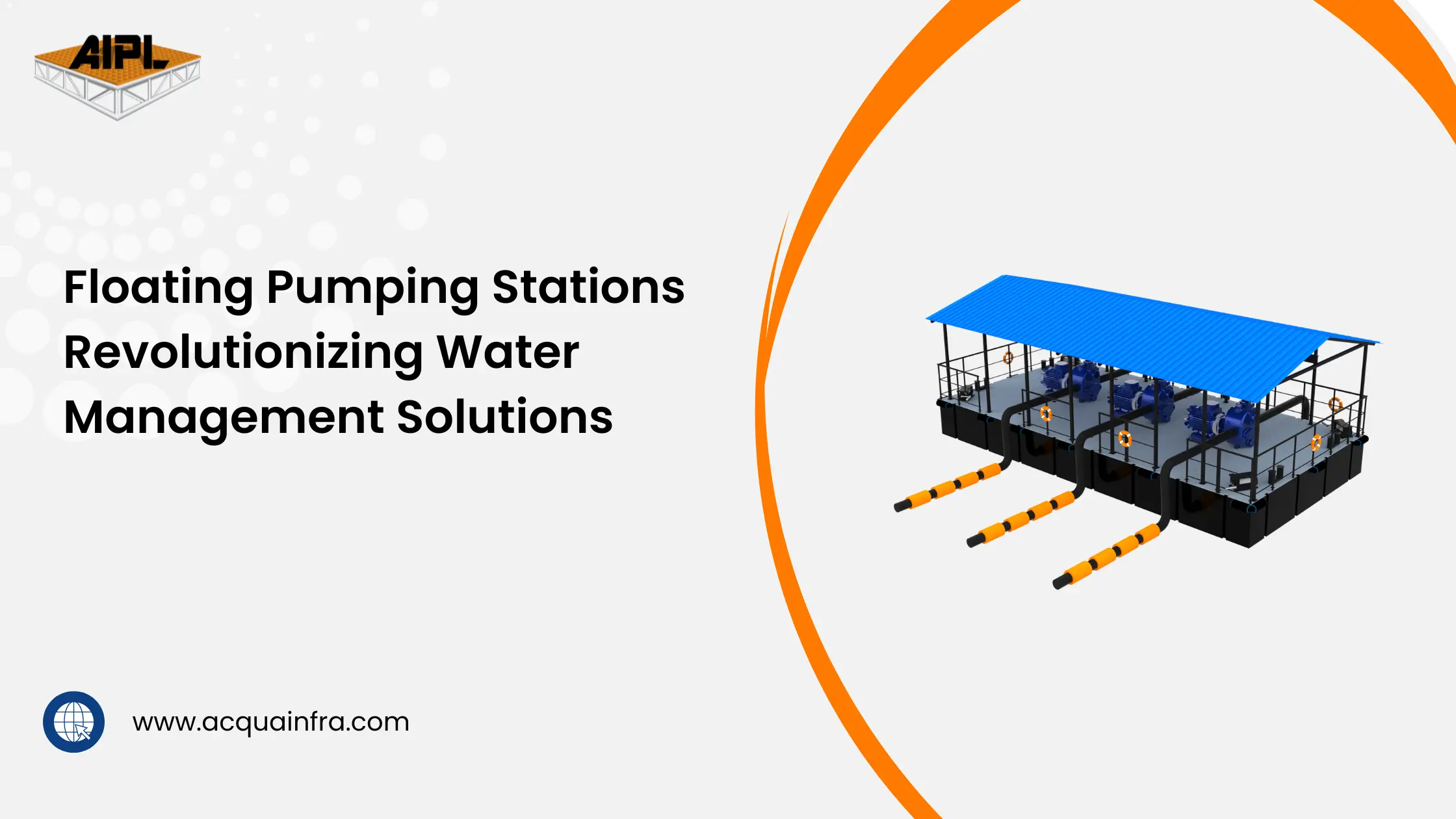

Floating pumping stations are the modern systems, utilized for water extraction, and water transfer from natural and/or artificial water reservoirs. These pumping systems, as their name implies, float on the water and are mounted on a buoyant platform. The floating characteristic permits these devices to respond during water level variations due to excessive rains, draughts, as well as seasonal differences in water levels.

In contrast to conventional pumping stations requiring major construction works, fixed constructions as well as substantial excavations, floating pumping stations are mounted directly on the water.

It is without a doubt the most remarkable feature of the floating pumping station that they have maximum versatility concerning elevation. These systems function regardless of the available water. There are no restrictions to their operations in a drought when water is scarce or in flood situations where the water level is high.

Installing pumping stations in the past required a lot of piping-pulling resources to build concrete structures and set the pumping stations over long distances. Floating pumping stations remove these costs because they are modular and do not require a complex set of logistic arrangements to install easily.

The use of floating pumping stations has little effect on the environment. There is no need for excavation, waterway habitats are protected, and it is possible to create such installations powered by renewable energy sources, which will significantly reduce CO2 emissions.

Maintenance of traditional pumps can be time-consuming, especially in the event the pumps are located in a high or low zone where access is difficult. Floating inline pumps only require surface placement making the structure itself easy to access making it faster to properly service the machine.

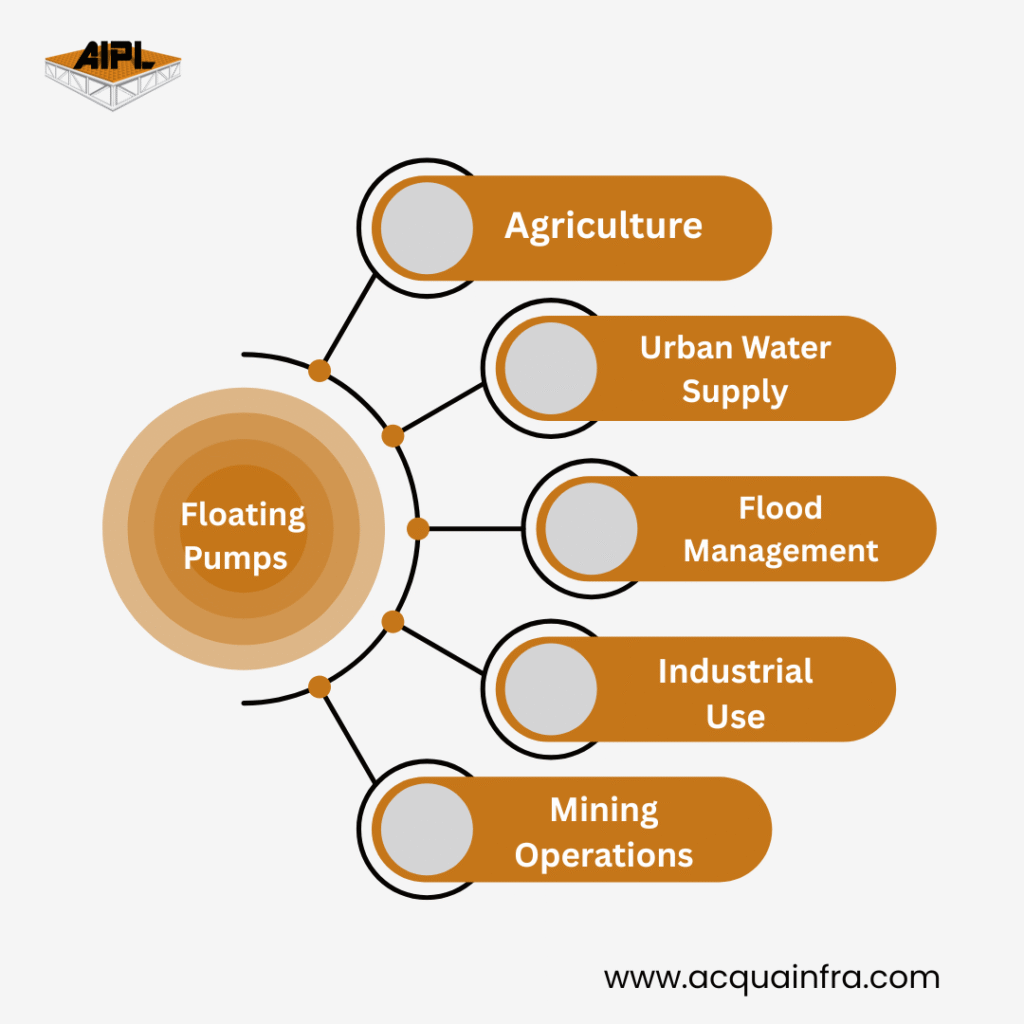

Floating pumping stations can be used for a large number of applications such as in irrigation, municipal water supply, flood control, etc

In response to the overwhelming need for water sources, floating pumping stations are designed with modular parts so they can be easily assembled, tailored, and expanded as required by the specific project.

These stations are constructed from high-quality materials that are resistant to weather and can survive extreme conditions like heavy rainfall, high winds, and prolonged exposure to the sun.

These sophisticated pumps are incorporated in floating pumping stations that require less energy to achieve high flow output, thereby making operations more efficient and cost-effective.

Every project comes with its unique specifications which is why floating pumping stations can be designed to meet project specifications including the quantity of water required, the pipes to be used and the type of energy to use.

Anchors and cables aid in the stabilization of the floating platforms such that even when they are in flowing or turbulent waters, the platforms are tethered securely in place.

Irrigation requires that the water supply is stable. Floating methods are able to draw in water from reservoirs, rivers and even lakes enabling farmers to have an endless source of water for irrigation during barren periods.

In places where cities and towns are located near water bodies,they are particularly great because they provide a reliable source of water for domestic use in urban centres. Their flexibility makes them more appropriate with the increasing urban populations.

In situations of floods, they are able to do away with excess water to enable the reduction of areas affected by floods, on residential and agricultural lands.

Industries, as an example, are in most cases, greatly in need of large volumes of water for cooling systems as well as in certain production phases.

In the area of mining, the issues of water management become important for fighting floods and providing underground mining.

It developed a system on a floating platform that supports the pump and all the equipment used above water rather than submerged. The platform is made of corrosion-resistant materials, and this ensures its durability.

For water extraction purposes at the floating platform, large-volume pumps are installed onboard. It means a significant amount of volume gets the job done therefore those pumps, ideal for industrial needs.

The water that is pumped off the surface is delivered through pipelines which are mounted on the floating station. Such pipelines can be made in different dimensions and lengths in accordance to the requirements of the project.

Even as cables or weights are used to anchor the floating platform, care is taken to achieve firmness. That way the station does not move during strong rushing currents and windy weather conditions.

At Acquafront Infrastructure, we pride ourselves on delivering innovative and reliable water management solutions. Here’s why we stand out:

The floating pumping station is built with modular technology, making it lightweight, easy to operate, and transportable by truck or trailer. It can be maintained on-site, eliminating the need for dry docking, which enhances convenience and reduces maintenance costs.

The products used for the installation of the floating pumping station are designed to meet IIT, IRS, and NABL certification standards

Years of experience in water infrastructure have given us knowledge of the challenges and solutions that have to be undertaken to ensure efficient management of water resources.

4. Customized Product

Keeping your specific requirements in mind, we carefully design each floating pumping station to ensure a perfect fit for your project. Moreover, by considering every detail, we guarantee a tailored solution that meets your needs. In addition, our modular floating pumping stations are fully expandable, allowing for seamless scalability as your project grows. As a result, you gain both flexibility and efficiency, ensuring long-term success.

Our systems employ high-quality materials, which ensure durability, reliability, and longevity.

From project planning and installation to maintenance, our team offers end-to-end support, ensuring a hassle-free experience.

While floating pumping stations are highly effective, they come with certain challenges:

Acquafront Infrastructure addresses these challenges with innovative designs, thorough site assessments, and expert engineering.

The future of floating pumping stations looks bright, and it is expected that technological advancements and the increased need to establish new practices for sustainable water management will contribute to its future. Advancements in smart automation, renewable energy integration, and IoT-based monitoring are sure to enhance their efficiency and usability.

As the world faces increasing water management challenges, floating pumping stations are being increasingly seen as part of the solution. Their adaptability, cost-effectiveness, and eco-friendly design position them as the technology of choice for the future.

Let Acquafront Infrastructure help you implement cutting-edge floating pumping stations for your project.

Contact us today to discuss your needs, and our team will guide you every step of the way.

Floating pumping stations would revolutionize the management of water with flexibility, efficiency, and sustainability. Floating pumping stations will change how people manage water during changing water levels due to their cost-effectiveness and wide range of applications.

Choose Acquafront Infrastructure Today and get associated with practitioners committed to excellence in the innovation of solutions for their clients. Let's work together to create a sustainable and efficient water management system for a better future.

A Floating Pump Pontoon is a modular floating platform designed to support pumps and associated equipment on water bodies. It provides stable, safe, and accessible infrastructure for water pumping applications in rivers, reservoirs, lakes, and industrial water sources.

Floating Pump Pontoons eliminate the need for heavy civil construction and land acquisition, which often delay projects and harm the environment. They ensure uninterrupted water access even during summer low levels or flood peaks, where fixed pump houses fail. Their modular and mobile nature provides flexibility for relocation or capacity expansion, while reducing downtime, accelerating project timelines, and cutting both capital and maintenance costs.

Urban & Rural Water Supply Projects, Irrigation Systems, Industrial Cooling Water Supply, Mining & Dredging Operations, Power Plant Intake Systems, Flood Management & Disaster Relief.

Public Health Engineering Departments, Power & Energy Utilities, Irrigation & Agriculture, Oil & Gas / Petrochemicals, Mining & Heavy Industry.

Steel (certified) is the primary material for structural components. Other components combine with HDPE or composite elements for buoyancy/support depending on load and site conditions.

Pumps are mounted on vibration-resistant skids with integrated piping, flexible couplings, and access platforms. The pontoons are engineered to handle static and dynamic loads.

The pontoon system rises and falls with water levels, ensuring uninterrupted pump operation and maintaining constant suction conditions.

Yes. The modular design allows pontoons to be transported in parts by road and assembled at the project site, making them ideal for remote and logistically challenging environments.

Small systems (up to 500 m³/hr): 2–3 months; Medium systems (500–2000 m³/hr): 3–6 months; Large systems (2000+ m³/hr): 6–9 months.

Bathymetric & Topographic Survey Data, Seasonal Water Level Variation Data, Pump Capacity & Type, Load & Utility Requirements, Site Accessibility & Deployment Constraints.

Yes. They are designed with redundancy in buoyancy, anchoring systems, and stability margins to withstand wind, waves, and current loads. Compliance with Indian Standards is ensured.

Anchoring solutions include mooring chains, piles, and deadweight anchors depending on depth, current, and soil strata.

Regular inspection of pontoons, coatings, anchoring systems, pump alignment, and preventive maintenance of pipelines and valves.

Yes. AMC covers structural inspections, preventive maintenance, and on-call support to ensure continuous and safe pumping operations.

Steel Modular Pontoons: 20–25 years with periodic maintenance; HDPE Floating Cubes: 10–15 years for light/temporary use cases.

All types of pumps including Vertical turbine, Centrifugal, Submersible, and Engine-driven pumps can be installed.

Yes. AIPL provides rental solutions for temporary or emergency requirements such as flood relief, mining dewatering, or irrigation needs.

Adaptability, Cost Efficiency, Faster Deployment, Low Downtime, Versatility, Scalability, and Safe Accessibility for operators.