As someone who works closely with marine infrastructure projects, I’ve seen how dock construction is no longer judged only by engineering strength or operational efficiency. Today, environmental responsibility is just as critical. Ports, marinas, and industrial jetties interact directly with sensitive aquatic ecosystems, and even small design decisions can have long-term environmental consequences.

This blog explains the environmental impacts of dock construction and use, along with practical mitigation measures, in a way that is easy to understand, realistic, and aligned with modern sustainability expectations.

Why Environmental Impact Matters in Dock Projects

Dock construction takes place at the boundary of land and water—an area that supports marine life, coastal vegetation, and local livelihoods. Without proper planning, dock projects can lead to:

- Disturbance of marine habitats

- Water pollution

- Shoreline erosion

- Long-term ecological imbalance

Responsible mitigation helps projects gain regulatory approvals, reduce community resistance, and ensure long-term operational sustainability.

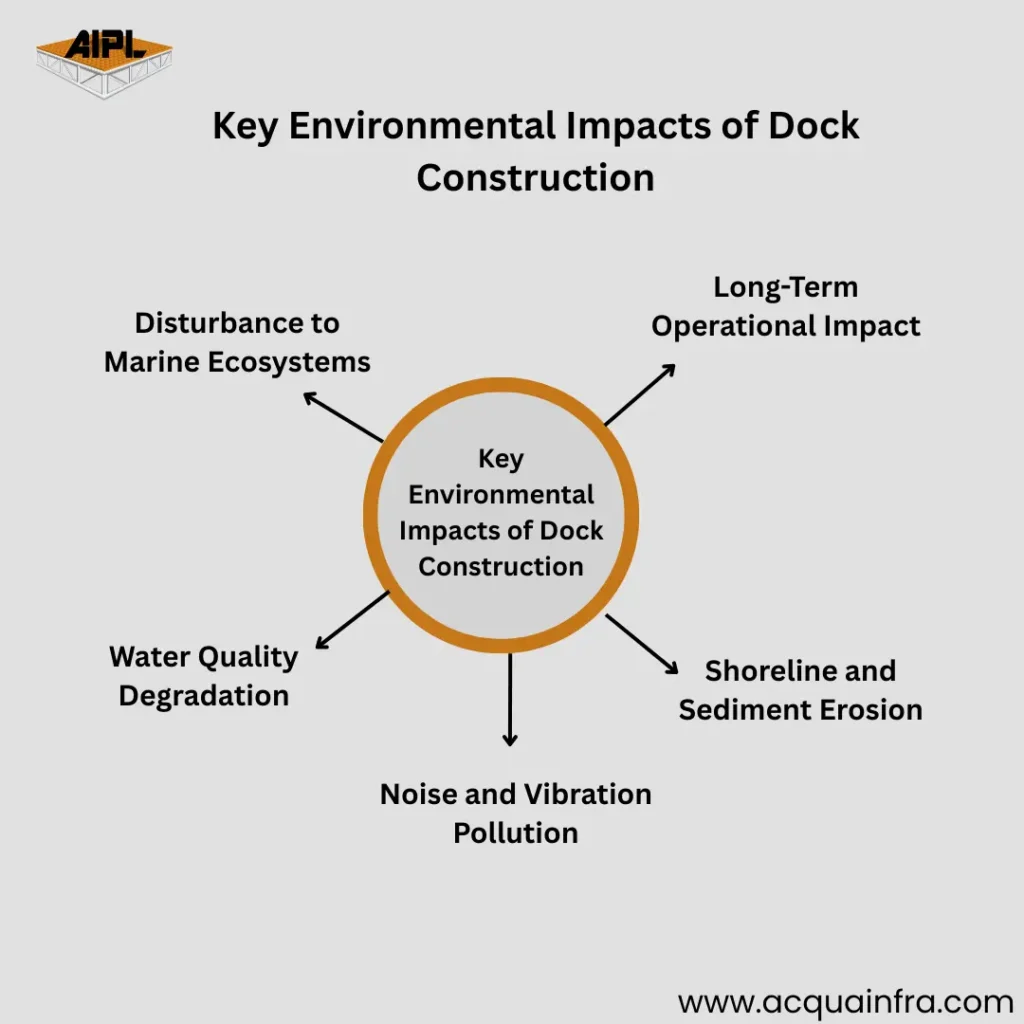

Key Environmental Impacts of Dock Construction

1. Disturbance to Marine Ecosystems

Pile driving, dredging, and seabed preparation can disturb benthic organisms, fish breeding grounds, and aquatic vegetation.

Real-Life Example: During jetty construction in riverine areas, improper piling schedules can disrupt fish spawning seasons.

2. Water Quality Degradation

Construction activities may increase turbidity and introduce oil, grease, or concrete residues into water bodies.

Practical Impact: Increased turbidity reduces sunlight penetration, affecting aquatic plant growth.

3. Noise and Vibration Pollution

Heavy equipment, piling, and vessel movement generate underwater noise that can stress marine fauna.

Real-Life Scenario: Marine mammals and fish are particularly sensitive to continuous underwater noise during construction phases.

4. Shoreline and Sediment Erosion

Improper dock alignment can alter natural water flow, leading to erosion or sediment buildup.

Practical Example: Fixed jetties without flow gaps may accelerate erosion on adjacent shorelines.

5. Long-Term Operational Impact

Dock usage introduces vessel traffic, waste generation, and accidental spill risks.

Environmental Mitigation Measures for Dock Construction

1. Environmentally Sensitive Design

- Use floating or hybrid dock systems to reduce seabed disturbance

- Provide water flow gaps in fixed structures

- Minimize footprint through optimized layout

Practical Use: Floating docks in marinas allow natural water circulation beneath the structure.

2. Controlled Construction Practices

- Schedule piling outside fish breeding seasons

- Use silt curtains during dredging

- Implement spill prevention measures

3. Material Selection and Sustainability

- Marine-grade concrete with low leaching

- FRP and HDPE components for corrosion resistance

- Durable materials to reduce frequent repairs

Real-World Insight: Longer-lasting materials reduce repeated construction disturbance.

4. Noise and Vibration Control

- Use vibration dampening techniques

- Opt for quieter piling methods where feasible

- Monitor underwater noise levels

5. Operational Environmental Controls

- Install waste collection systems

- Implement oil spill containment measures

- Regular inspection and maintenance

Practical Real-Life Applications of Mitigation Measures

- Marinas: Floating docks with eco-friendly floats reduce seabed shading and allow aquatic life to thrive.

- Ports: Fender systems absorb berthing impact, minimizing structural repairs and repeated underwater work.

- Industrial Jetties: Hybrid docks reduce stress on fixed structures while accommodating tidal movement.

These measures show how environmental care and operational efficiency go hand in hand.

How AIPL Can Assist in Environmental Impact Mitigation for Dock Projects

Acquafront Infrastructure Pvt. Ltd. (AIPL) integrates environmental responsibility into every stage of dock development.

AIPL assists clients with:

- Environmentally compliant dock system design

- Selection of low-impact construction methods

- Use of sustainable marine-grade materials

- Support for regulatory and environmental approvals

- Long-term maintenance planning to minimize repeated disturbance

AIPL’s approach balances infrastructure performance with ecological sensitivity.

AIPL’s Proven Experience in Environmental Impact Mitigation for Dock

1. Floating CNG Filling Station – Khirkiya Ghat, Varanasi (2021)

- Client: GAIL / MECON India Pvt. Ltd.

- Significance: World’s first floating CNG filling station

- Environmental Relevance:

- Reduced air, water, and noise pollution on the Ganga

- Enabled shift from diesel to cleaner CNG boats

- Floating structure avoided permanent riverbed disturbance

2. Floating CNG Mobile Refuelling Unit (MRU) – Ravidas Ghat, Varanasi (2023)

- Client: GAIL / MECON India Pvt. Ltd.

- Environmental Relevance:

- Mobile floating solution reduced need for multiple shore-based stations

- Supports clean inland water transport

- Minimal construction footprint

3. I-Ghat Project (Solar Floating Infrastructure) – Kaushambi (2022)

- Client: NTT DATA

- Environmental Relevance:

- Floating solar power plant

- Battery charging for electric boats

- Direct contribution to renewable energy & emission reduction

4. Cruise Passenger Jetties – Varanasi (2020)

- Client: Planner India Pvt. Ltd.

- Commissioned by: UPRNN

- Environmental Relevance:

- HDPE modular floating jetties

- Reduced shoreline excavation

- Improved passenger handling with low ecological disturbance

5. Floating Pump Pontoons – PHED Odisha & Ultratech Cement (Multiple Years)

- Locations: Odisha, Madhya Pradesh

- Environmental Relevance:

- Floating intake systems adapt to fluctuating water levels

- Avoid repeated dredging and intake reconstruction

- Long-term sustainable water management

Conclusion

Environmentally responsible dock construction protects marine ecosystems while ensuring long-term project success. Smart design and mitigation measures make sustainable marine infrastructure achievable.

Frequently Asked Questions

Does dock construction always harm the environment?

No, with proper planning and mitigation, impacts can be minimized.

Are floating docks more environmentally friendly?

Yes, they reduce seabed disturbance and allow natural water flow.

What is turbidity control?

It limits sediment spread during construction.

What materials are environmentally preferred?

Durable, corrosion-resistant, low-leaching materials.

Can docks be designed to support marine life?

Yes, through eco-sensitive designs.

Do regulations mandate mitigation measures?

Yes, under CRZ and environmental laws.

How often should environmental monitoring be done?

During construction and regular operations.

Can old docks be made eco-friendly?

Yes, through refurbishment and upgrades.

Does dock lighting affect marine life?

Yes, improper lighting can disturb ecosystems.

Planning a dock project with environmental compliance in mind? Connect with AIPL for expert guidance on eco-friendly dock systems that meet operational needs while respecting nature.

About the Author

Mr. Ankit Patel, Director & CEO

- Industrial expertise in Business Development, Operations, Finance & Administration, and Product development.

- Navkriti Medal issued by the Indian Institute of Technology (BHU), Vara