When working on waterfront infrastructure projects, one question always comes up early:

Which dock system is right for this location and usage?

From my experience as a digital marketer working with marine infrastructure brands, I’ve learned that dock systems are not one-size-fits-all solutions. Water depth, tidal variations, load requirements, and long-term maintenance all play a critical role.This guide breaks down fixed, floating, and hybrid dock systems in simple terms, helping port authorities, marina developers, and industrial operators make informed decisions.

A dock system is a marine structure designed to support vessel berthing, loading, unloading, passenger movement, and waterfront access. Dock systems form the operational heart of ports, jetties, marinas, and industrial terminals.

Modern dock systems are engineered to balance:

Safety and durability

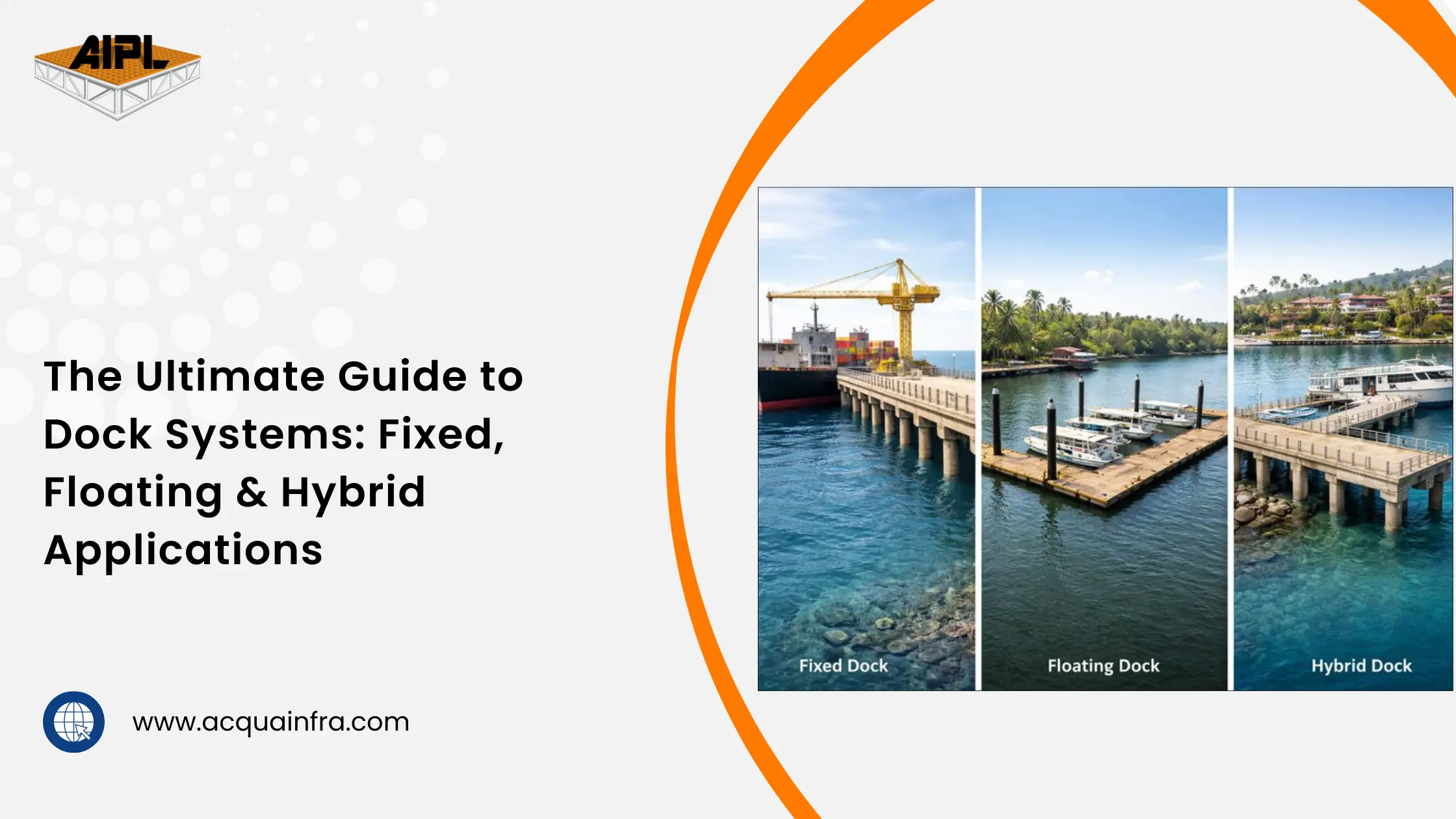

Types of Dock Systems Explained

Fixed docks are permanently constructed structures supported by piles driven into the seabed. They remain at a constant elevation regardless of water level changes.

Best for locations with minimal tidal variations.

Floating docks are modular platforms that rise and fall with water levels, connected to the shore using gangways and guided by piles.

Best for rivers, lakes, and coastal areas with high tidal variations.

Hybrid dock systems combine the strength of fixed structures with the flexibility of floating platforms.

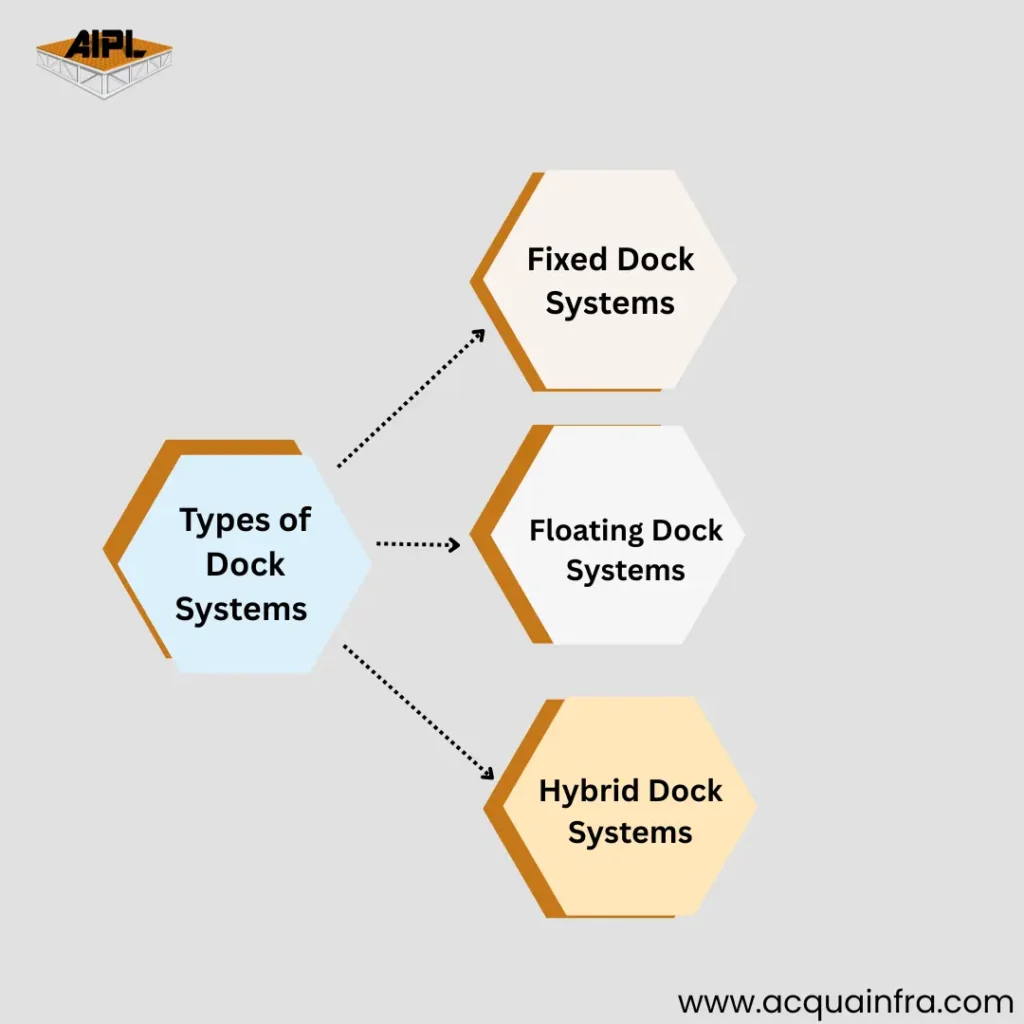

| Feature | Fixed Dock | Floating Dock | Hybrid Dock |

| Water Level Adaptability | Low | High | Medium–High |

| Load Capacity | Very High | Moderate | High |

| Installation Time | Longer | Faster | Moderate |

| Maintenance | Moderate | Low–Moderate | Balanced |

| Best Use | Heavy industry | Recreational & ferry | Mixed operations |

Before finalizing a dock type, consider:

Choosing the right system early reduces maintenance costs and operational risks.

Acquafront Infrastructure Pvt. Ltd. (AIPL) specializes in designing, manufacturing, and installing dock systems tailored for Indian marine conditions.

With extensive experience across riverine, coastal, and industrial projects, AIPL delivers dock systems that combine safety, performance, and longevity.

Fixed Dock Systems:

Major commercial ports such as Jawaharlal Nehru Port (JNPT), Mumbai use fixed jetties for heavy container handling and long-term industrial operations due to their high load-bearing capacity and structural stability.

Floating Dock Systems:

Passenger ferry terminals in Kerala and riverfront ghats on the Ganga commonly use floating docks to accommodate seasonal water-level variations and ensure safe boarding throughout the year.

Hybrid Dock Systems:

Multi-purpose waterfront developments and coastal tourism terminals in India and Southeast Asia often adopt hybrid dock systems, combining fixed approach structures with floating pontoons for flexibility and operational efficiency.

Choosing the right dock system is crucial for safe, efficient, and future-ready waterfront operations. Understanding the strengths of fixed, floating, and hybrid docks helps ensure long-term performance and cost efficiency.

Planning a new dock or upgrading an existing waterfront facility? Partner with AIPL for expertly engineered dock systems designed to perform in real-world marine conditions. Get reliable solutions that support your operations today and well into the future.

Frequently Asked Questions

Fixed docks remain stationary, while floating docks move with changing water levels.

Customizable floating docks and marina systems can be purchased from Acquafront Infrastructure Pvt. Ltd., offering tailored layouts, finger pontoons, gangways, mooring systems, and utility integration based on site-specific requirements and vessel traffic.

Floating or hybrid dock systems perform best in tidal environments.

Floating or hybrid dock systems perform best in tidal environments.

It combines fixed structural elements with floating platforms for flexibility and strength.

Well-maintained dock systems can last 25–40 years or more.

Floating docks generally require less structural maintenance.

Floating and hybrid systems are especially easy to expand.

Concrete, steel, HDPE, and composite materials are commonly used.

Installation time varies from a few weeks to several months.

Hybrid dock systems often offer the best lifecycle value.

Fixed and hybrid docks are ideal for heavy vessel operations.