When discussing pontoon durability, most conversations focus on float materials, load capacity, or mooring systems. However, two often-overlooked components — cleats and fenders — play a critical role in determining the long-term performance, safety, and lifespan of floating pontoons.

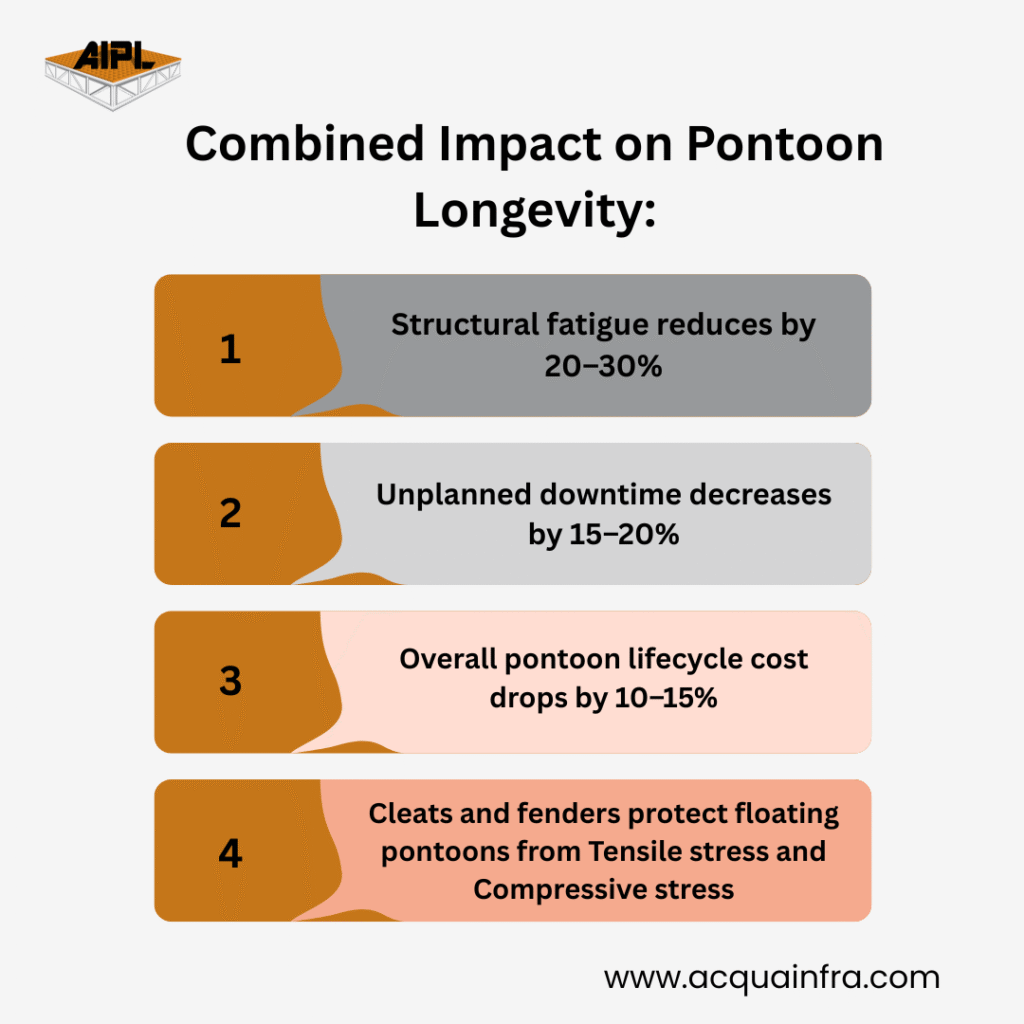

Incorrect selection or poor placement of cleats and fenders can accelerate structural wear, increase maintenance costs, and reduce pontoon life by 20–30% over time. This blog explores how these small components create a big impact on pontoon longevity.

Cleats are load-bearing fittings used to secure mooring lines from boats or barges to floating pontoons. While they appear simple, cleats directly influence load transfer, stress concentration, and deck integrity.

Well-designed cleat systems:

In high-traffic floating jetties, poorly sized cleats can cause deck fatigue within 2–3 years, whereas properly rated cleats can extend pontoon service life by 25% or more.

Cleat placement is as important as cleat strength. Incorrect spacing can lead to uneven force distribution during berthing and unberthing operations.

Key considerations include:

Engineering studies show that optimized cleat placement can reduce deck stress by 15–20%, significantly lowering long-term repair requirements.

Fenders act as the first line of defense between vessels and pontoons. Their primary role is to absorb kinetic energy during berthing, preventing direct impact damage to both the pontoon and the vessel.

High-quality fender systems:

Without adequate fendering, repeated low-speed impacts can shorten pontoon lifespan by up to 30%, especially in high-use commercial docks.

Not all fenders perform the same. Fender selection must align with:

Properly selected fenders reduce maintenance intervention by 20–25% and significantly improve operational safety in floating jetties and pontoons.

Cleats and fenders work together to protect floating pontoons from two major threats:

When designed as an integrated system:

This makes cleats and fenders not just accessories, but critical structural components in any pontoon system.

Even high-quality cleats and fenders require periodic inspection. Neglecting these components often leads to secondary structural damage.

Best practices include:

Proactive maintenance can extend pontoon operational life by 5–10 years, depending on usage conditions.

Pontoon longevity is not defined solely by floats or structural frames. Cleats and fenders directly influence how forces are managed, absorbed, and transferred across the pontoon system. When engineered correctly, they significantly reduce wear, improve safety, and protect long-term investment.

For commercial docks, floating jetties, and modular pontoon systems, focusing on these details is what separates short-term solutions from truly durable infrastructure.

How do cleats affect pontoon lifespan?

Cleats control how mooring loads transfer to the structure; poor design can accelerate deck fatigue and structural damage.

Are fenders necessary for low-speed berthing areas?

Yes. Even low-speed impacts cause cumulative damage over time without proper energy absorption.

How often should cleats and fenders be inspected?

Visual inspections every 3 months and detailed checks annually are recommended.

Can upgrading fenders reduce maintenance costs?

Yes. High-energy absorption fenders can lower repair and downtime costs by up to 25%.

Designing a long-lasting pontoon system goes beyond floats and frames.

Partner with Acquafront Infrastructure (AIPL) for engineered pontoon solutions with correctly designed cleats, fenders, and mooring systems — built for durability, safety, and long-term performance.

👉 Visit www.acquainfra.com or connect with our experts to optimize your floating infrastructure today.