Commercial docks are critical interfaces between marine vessels and land-based logistics. Whether designed for cargo handling, passenger movement, or industrial operations, a well-planned commercial dock directly impacts operational efficiency, safety, and lifecycle costs.

With increasing vessel traffic and larger berth requirements, modern dock design must balance layout optimization, structural strength, and berthing performance — while adapting to local water conditions and future scalability.

Dock layout determines how efficiently vessels berth, cargo moves, and operations scale over time. Poor layout planning can increase vessel turnaround time by 15–25%, directly affecting port productivity.

Key layout considerations include:

In multi-use terminals, combining fixed dock sections with floating jetties or pontoons often improves flexibility and reduces congestion during peak operations.

The structural system of a commercial dock must safely transfer loads from vessels, cargo, and equipment into the foundation while withstanding marine forces.

Important structural aspects include:

For sites with variable water levels, integrating floating pontoons or hybrid dock systems reduces structural stress and minimizes maintenance costs over time.

Efficient berthing design improves safety and reduces vessel damage during docking operations. Inadequate berthing systems can increase maintenance incidents by 20–40%.

Key berthing elements include:

Floating jetties and pontoons are increasingly used as berthing interfaces in commercial docks, as they maintain consistent freeboard and reduce vessel downtime during water-level fluctuations.

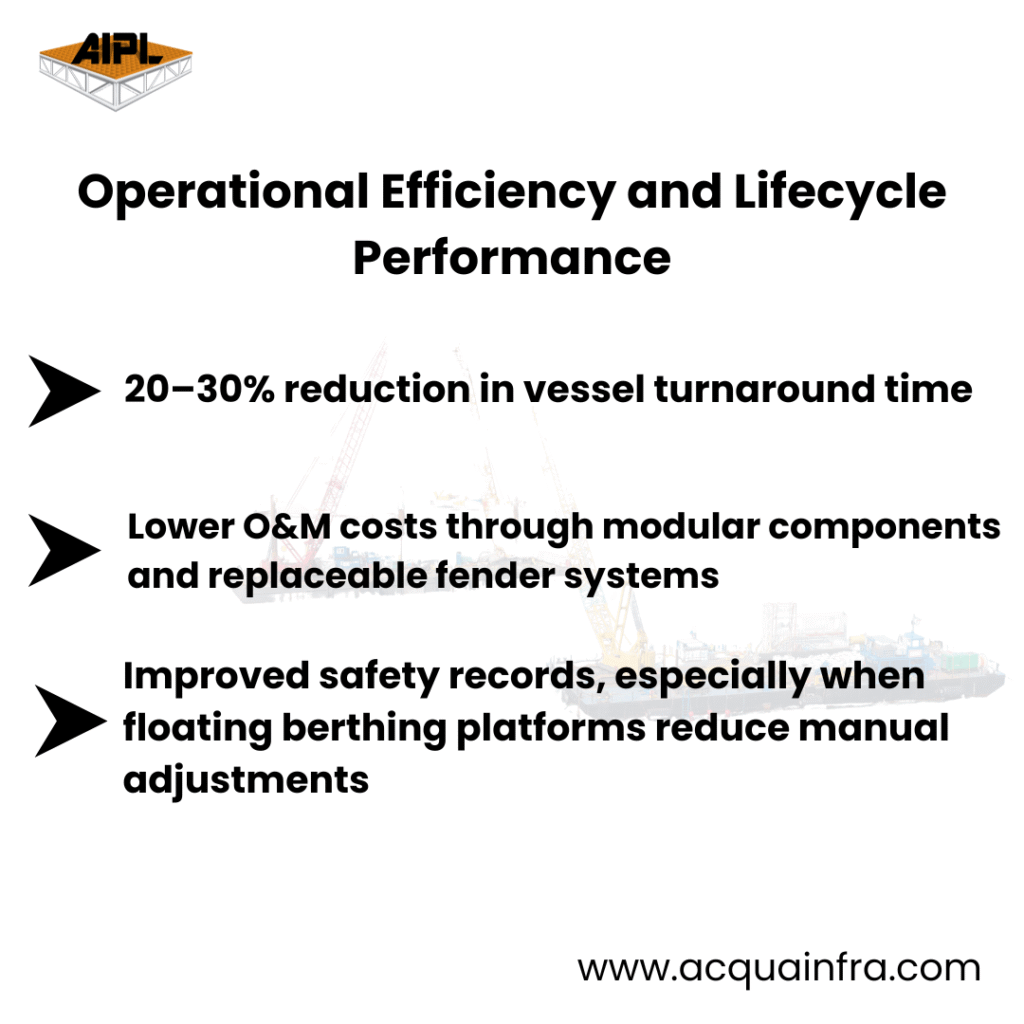

Beyond initial construction, commercial dock performance is measured by long-term operability and cost efficiency.

Well-designed docks typically deliver:

Modular dock components such as floating jetties, pontoons, and barges also allow phased upgrades without shutting down operations — a major advantage for active commercial terminals.

Commercial dock design is no longer just about building a strong structure — it’s about creating a scalable, efficient, and resilient marine interface. By carefully planning layout, selecting the right structural system, and optimizing berthing arrangements, developers can significantly improve operational performance and asset lifespan.

As commercial marine activity continues to grow, docks that integrate fixed structures with floating jetties and pontoons will remain best positioned to handle changing demands.

What is the most critical factor in commercial dock design?

Balancing layout efficiency with structural capacity and safe berthing performance.

When should floating jetties be used in commercial docks?

Floating jetties are ideal where water levels vary significantly or where future expansion is expected.

How long does a commercial dock typically last?

With proper design and corrosion protection, fixed docks can last 40–60 years, while floating pontoons typically last 20–25 years.

Can commercial docks be expanded later?

Yes. Modular floating pontoons and hybrid dock systems allow expansion with minimal disruption.

Planning a commercial dock or upgrading an existing terminal?

Partner with Acquafront Infrastructure Pvt. Ltd. (AIPL), India’s trusted manufacturer of floating jetties, pontoons, barges, and modular dock systems.

👉 Visit www.acquainfra.com or connect with our experts to design a dock that delivers long-term performance and reliability.