Efficient mine dewatering is not optional, it directly impacts production, equipment safety, and operational continuity. Yet most mines still rely on traditional land-based pump setups, which require civil works, frequent pump shifting, and continuous manpower. This leads to avoidable downtime, higher costs, and unsafe work conditions.

Floating dewatering pump pontoons eliminate these inefficiencies completely. By placing pumps directly on water, with stable, modular pontoons, mines achieve up to 30% cost savings and 25–35% reduction in downtime right from the first deployment.

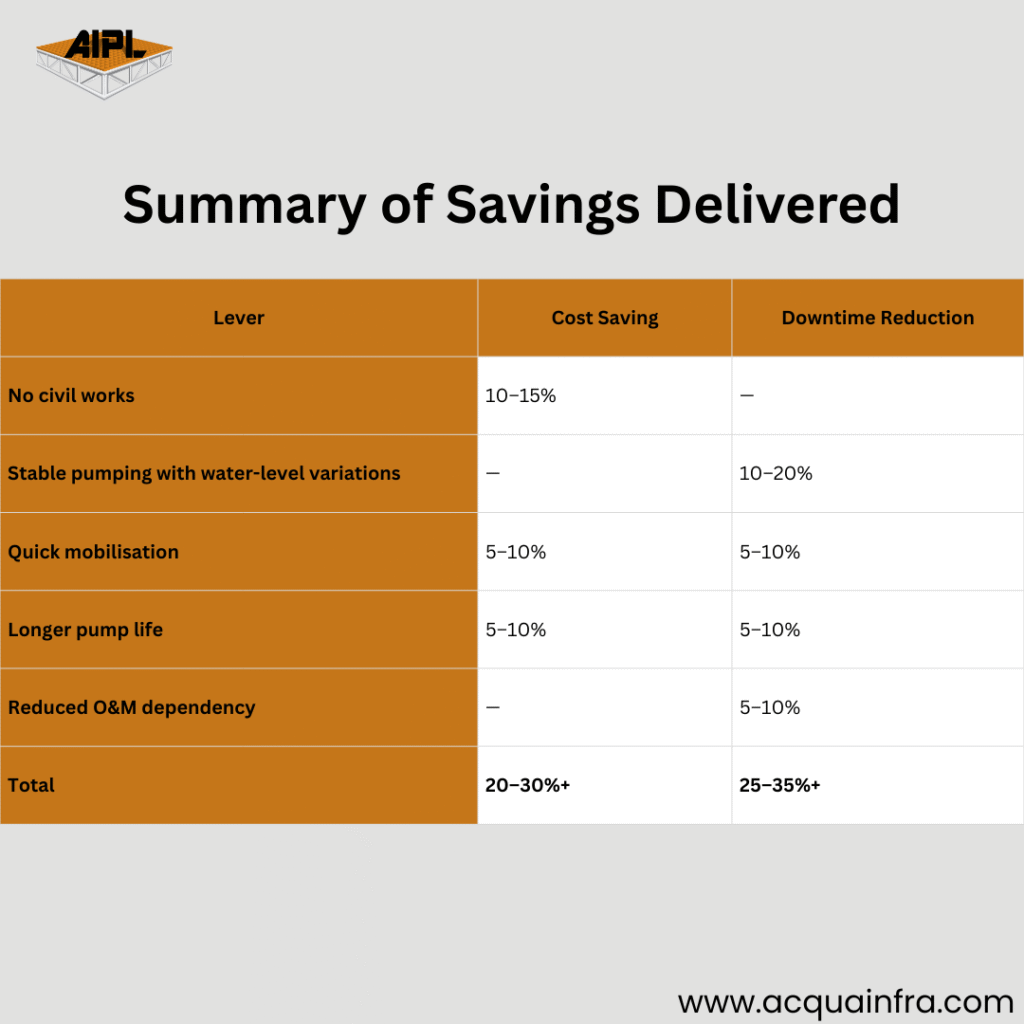

Below is a clear breakdown of how floating pump pontoons deliver measurable impact:

Conventional dewatering systems depend on pump houses, foundations, embankments, and pipe supports. Every shift in water level demands reconstruction or relocation.

Floating pontoons remove all civil infrastructure needs, allowing direct deployment on water.

Result:

As mine pits deepen, water levels fluctuate daily. Land-based pumps must be repeatedly moved to maintain suction depth — causing shutdowns and manpower delays.

Pontoons float automatically, keeping pump suction at the perfect level.

Result:

Modular pontoons are compact, lightweight, and can be transported to remote mines without heavy equipment.

Deployment takes hours instead of days.

Result:

Floating pontoons provide a low-vibration and properly aligned platform, reducing mechanical stress on pumps.

Result:

With pumps positioned directly above water, access becomes significantly easier.

Result:

Deployments at Vedanta, UltraTech, Birla Cements, OMPL, ERPMC, and others consistently deliver:

Across all sites, a minimum 30% improvement is seen in cost or operational efficiency.

Upgrade to AIPL’s engineered pump pontoons and unlock 30% cost savings with zero civil work and 24×7 pumping reliability.

👉 Contact us today for a customised mining dewatering solution.

For mines struggling with high dewatering costs, unpredictable water levels, and frequent pump breakdowns, floating dewatering pump pontoons offer the most reliable and cost-optimized solution. Backed by proven deployments across India, these systems guarantee faster commissioning, lower OPEX, and consistent pump uptime — all critical for uninterrupted mining operations.

FAQs

An inflatable, module-based building built to float structures like buildings, pumps, or utilities above water, best suited in aquatic or flood-prone areas.

Yes. With a good design and anchoring, they can last for decades as homes, pump stations, or public facilities.

It floats and stabilizes a water pump, enabling water to be pumped efficiently even at fluctuating levels of water or during floods.

Although they are more expensive than conventional structures to implement initially, the cost savings on maintenance, disaster relief, and adaptability in the long term make them inexpensive.

AIPL employs tailored engineering, industrial-grade materials, and a modularity concept, which enables their solutions to be scalable, resilient, and easy to roll out.

Steel (certified) is the primary material for structural components. Other components combine with HDPE or composite elements for buoyancy/support depending on load and site conditions.

Pumps are mounted on vibration-resistant skids with integrated piping, flexible couplings, and access platforms. The pontoons are engineered to handle static and dynamic loads.

The pontoon system rises and falls with water levels, ensuring uninterrupted pump operation and maintaining constant suction conditions.

Yes. The modular design allows pontoons to be transported in parts by road and assembled at the project site, making them ideal for remote and logistically challenging environments.

Small systems (up to 500 m³/hr): 2–3 months; Medium systems (500–2000 m³/hr): 3–6 months; Large systems (2000+ m³/hr): 6–9 months.

Yes. They are designed with redundancy in buoyancy, anchoring systems, and stability margins to withstand wind, waves, and current loads. Compliance with Indian Standards is ensured.

Anchoring solutions include mooring chains, piles, and deadweight anchors depending on depth, current, and soil strata.

Regular inspection of pontoons, coatings, anchoring systems, pump alignment, and preventive maintenance of pipelines and valves.

Yes. AMC covers structural inspections, preventive maintenance, and on-call support to ensure continuous and safe pumping operations.

Steel Modular Pontoons: 20–25 years with periodic maintenance; HDPE Floating Cubes: 10–15 years for light/temporary use cases.

All types of pumps including Vertical turbine, Centrifugal, Submersible, and Engine-driven pumps can be installed.

Yes. AIPL provides rental solutions for temporary or emergency requirements such as flood relief, mining dewatering, or irrigation needs.

Adaptability, Cost Efficiency, Faster Deployment, Low Downtime, Versatility, Scalability, and Safe Accessibility for operators.