Designing a small marina requires a careful balance between functionality, vessel safety, and long-term operational efficiency. As waterfront tourism and recreational boating grow by nearly 18% year-on-year in India, developers are seeking compact marinas that deliver smooth berthing, easy navigation, and efficient use of water space.

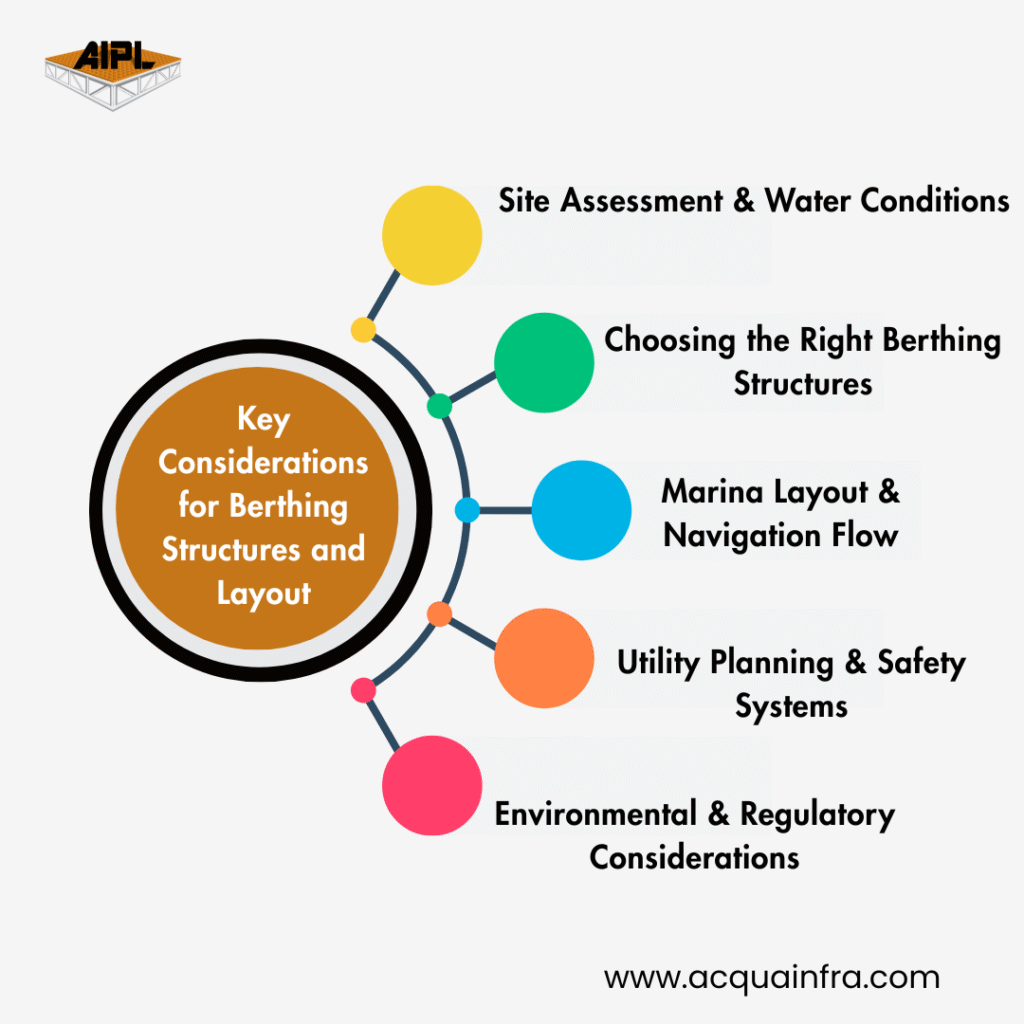

This short guide highlights the key design considerations for small marina layouts — especially focusing on berthing structures, floating jetties, pontoons, and access planning.

Before any marina design begins, engineers evaluate:

Small marinas commonly use floating pontoons for berthing due to adaptability and reduced civil work.

For heavy-duty or commercial berths, pile-secured pontoons ensure lateral stability even during high-traffic operations.

A good marina layout improves vessel circulation and maximizes usable space.

Key layout practices include:

Compact marinas benefit from L-shaped or linear layouts, reducing structural costs by 15–20% while offering full berthing efficiency.

Essential utilities define the operational quality of a marina:

Safety is further strengthened by using anti-slip pontoon decking, marine-grade railings, and well-placed life-saving equipment.

Modern marinas prioritize sustainability:

Designing a small marina blends strategic engineering with efficient berthing planning. By choosing the right pontoon systems, optimizing marina layout, and integrating essential utilities, developers can create compact yet high-performance marinas that support tourism, recreation, and long-term waterfront growth.

1. What type of berthing is best for small marinas?

Floating pontoons are preferred due to adaptability, fast installation, and lower civil work.

2. How wide should marina walkways be?

Typically 2–3 meters, depending on expected traffic.

3. Are floating jetties durable for commercial use?

Yes — steel-reinforced or HDPE pontoons last 20–25 years with low maintenance.

4. What reduces wave impact inside the marina?

Breakwaters or wave attenuators cut wave intensity by 40–60%.

Planning to build a small marina with high-efficiency berthing structures?

Partner with Acquafront Infrastructure Pvt. Ltd. (AIPL) — India’s trusted manufacturer of floating jetties, pontoons, and modular marina solutions.

👉 Visit acquainfra.com or contact our team for custom marina design support.