India’s coastline stretches over 7,500 km, connecting vibrant ports, fishing harbors, and emerging waterfront developments. As marine activity grows across rivers, lakes, and coastal zones, the need for safe, reliable, and modular docking solutions has never been greater. Pontoon docks and mooring systems are at the heart of this transformation — blending engineering precision with adaptability to meet diverse marine demands.

This guide walks you through everything you need to know about pontoon docks and mooring systems — from their types and uses to how they’re reshaping India’s maritime and inland water infrastructure.

A pontoon dock, often referred to as a floating dock, is a buoyant platform designed to rise and fall with water levels. Unlike traditional fixed jetties, pontoons offer flexibility, easy installation, and low environmental impact — making them ideal for both commercial and recreational applications.

These docks are typically made from HDPE, concrete, or steel modules, connected to form a stable platform that can support vessels, machinery, and even large events. The modular nature allows them to be customized, extended, or relocated with ease — ensuring long-term utility across various projects.

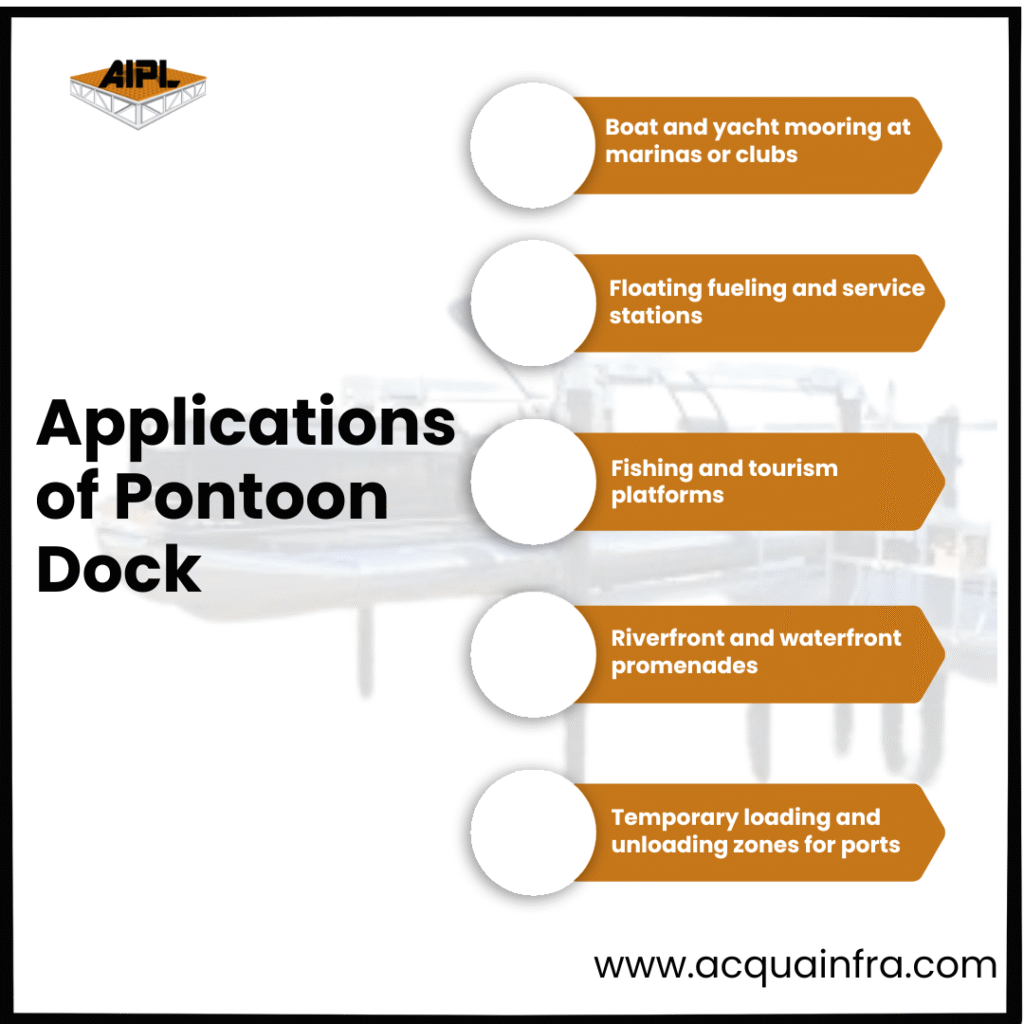

Common Applications Include:

In India, modular pontoon docks have been successfully deployed across Varanasi, Kochi, and Mumbai, under initiatives like Namami Gange and Sagarmala — showcasing how these systems are strengthening both inland and coastal connectivity.

When choosing between fixed and floating systems, the key lies in understanding the site conditions and operational needs.

Fixed Docks:

Built on piles or concrete foundations, fixed docks are ideal for areas with stable water levels. They offer superior load-bearing capacity, making them suitable for heavy cargo handling, industrial use, or permanent installations like shipyards.

Floating Docks:

Floating docks, on the other hand, are anchored to the seabed but remain buoyant — rising and falling with the tide. This flexibility makes them perfect for rivers, lakes, and tidal regions where water levels vary significantly.

In India’s inland waterways — such as the Ganga and Brahmaputra river systems — floating pontoons have proven invaluable for cargo handling, river cleaning projects, and ferry terminals where conventional docks are impractical.

A mooring system is what keeps a floating dock stable and secure against currents, winds, and vessel movement. It’s the foundation of safety and performance for any pontoon setup.

There are several types of mooring systems used depending on the site:

Modern mooring designs are now being enhanced with smart sensors and corrosion-resistant materials to ensure long-term performance with minimal maintenance.

India’s floating dock industry is rapidly innovating with materials and design. Traditional steel and wood constructions are being replaced with HDPE, FRP, and hybrid concrete pontoons that offer:

Manufacturers like Acqua Infra are leading this shift, offering modular pontoon systems engineered for both inland and coastal applications. Their structures are designed to handle challenging weather conditions while meeting international safety standards.

Floating docks and modern mooring systems contribute to sustainable marine development. Since they require minimal seabed alteration, they’re ideal for eco-sensitive zones such as riverfronts, wetlands, and reservoirs.

They also support clean energy and water projects — for instance, modular pontoons are being used in floating solar installations and river cleaning platforms under programs like Namami Gange. These applications show how functionality and environmental responsibility can go hand-in-hand.

Selecting the right solution depends on your location, purpose, and environmental factors.

Key Considerations:

Consulting with marine infrastructure experts ensures a safe, durable, and compliant installation.

As India’s maritime and inland waterways continue to evolve, pontoon docks and mooring systems will define the next generation of coastal infrastructure. From smart marinas in Kochi to floating fueling stations in Varanasi, the shift toward modular, floating, and sustainable solutions is clear.

These innovations promise not only efficiency and adaptability but also help India align with global trends in blue economy growth and eco-friendly marine engineering.