India’s ports are the lifelines of its trade network, handling nearly 95% of the country’s external trade by volume. With rising cargo traffic, modernization is no longer an option but a necessity. One of the most effective ways this modernization is happening is through the adoption of modular pontoons and barges — versatile, scalable, and sustainable marine infrastructure solutions reshaping the future of port development.

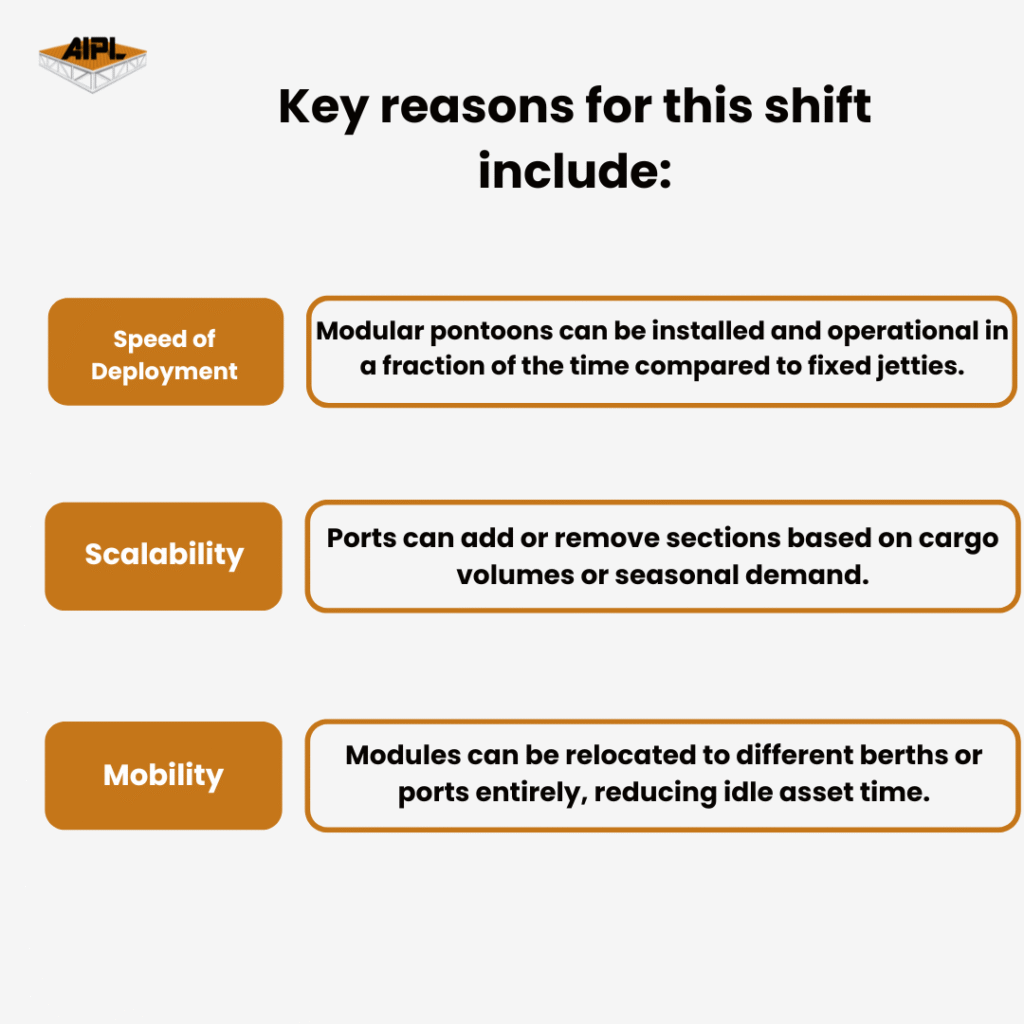

Traditional port construction involves extensive civil engineering, long build times, and large capital expenditure. As trade demands evolve faster than physical expansion can keep up, ports are turning to floating modular solutions that can be deployed in weeks instead of years.

These benefits make modular pontoons ideal for intermediate and satellite ports, helping them accommodate additional cargo or act as transit hubs during infrastructure upgrades.

One of the strongest value propositions of modular pontoons and barges lies in their contribution to operational efficiency and flexibility.

At busy ports such as Mumbai Port, Paradip Port, and Kandla Port, floating pontoons have been deployed to:

For example, Vizag and Kochi ports have utilized modular barge platforms to support maintenance dredging and serve as mobile workshops — eliminating downtime and improving workflow efficiency.

These modular systems can even be integrated with automated cranes, fueling units, and control systems, enhancing both capacity and safety at the same time.

Sustainability is a major consideration in today’s port development landscape. Modular pontoons and barges align perfectly with eco-friendly construction and operation principles.

This makes them an integral part of India’s Sagarmala and Maritime India Vision 2030 initiatives, both focused on developing sustainable and cost-efficient port infrastructure.

India’s inland waterway network is rapidly transforming logistics and trade connectivity. Modular pontoons and barges play a vital role in expanding these waterways into fully functional trade routes.

Case Example:

In Varanasi, under the Namami Gange project, modular pontoons were used to develop the Floating CNG Fueling Station, India’s first of its kind. It not only supports clean energy but also demonstrates how floating infrastructure can support inland port functions efficiently.

Similarly, on the Hirakud Reservoir and National Waterway 1, modular barges are enabling the movement of construction materials, fuels, and bulk cargo — showing how scalable solutions can strengthen both economic and environmental objectives.

With trade volumes increasing and new coastal economic zones being planned, modular pontoons and barges are set to become the core enablers of modern port infrastructure.

As India’s ports — such as Jawaharlal Nehru Port (JNPT), Kandla, and Chennai — expand their operational footprints, the use of modular pontoons will ensure agility, sustainability, and long-term adaptability.

Contact Acquafront Infrastructure Pvt. Ltd. (AIPL) today to consult with our industrial experts, learn more about our patent-recognized modular solutions, and start designing your custom floating infrastructure for cost-efficient, rapid port development. Email us at admin@acquainfra.com or call us to discuss your project needs.

Port development in India is moving toward flexibility, modularity, and sustainability. Modular pontoons and barges not only enable faster and cost-effective expansion but also ensure that ports remain future-ready in a changing trade environment. Whether for cargo handling, fuel storage, or maintenance operations, modular marine infrastructure is setting new benchmarks in how India connects its shores to the world.

Acquaworks is a modular heavy-duty pontoon system designed to convert any waterbody into a safe, stable, and high-performance worksite for cranes, excavators, dredgers, and piling rigs.

It features reinforced interlocking decks, spud wells, winch anchoring, non-slip surfaces, guardrails, and safe crew access.

- Acquaworks Lift – Crane Operations

- Acquaworks Dig/Dredge – Excavation & Dredging

- Acquaworks Pile/Drill – Piling & Drilling

Length: 18–30 m, Width: 9–15 m, Depth: 1.2–1.8 m

6–8 t/m² across all models.

- Lift: up to 60 tons

- Dig/Dredge: up to 45 tons

- Pile/Drill: up to 50 tons

Yes, spud wells/spud-assisted systems are available in all models.

Bollards, winches, guardrails, fenders, gensets, fire extinguishers, propulsion units.

Heavy-duty floating crane operations with reinforced deck grillage and wear plates.

By using spud anchoring, wear plates, wide access zones, and predictable radius management.

Water-based excavation and dredging using excavators, suction heads, and slurry pumps.

Yes, it supports silt curtains and debris screens.

Marine piling and drilling with vibro hammers, impact hammers, and rotary rigs.

Through integrated reaction points, tie-downs, and guide posts.

Yes, it is modular, transport-friendly, and quick to reconfigure.

Non-slip decks, guardrails, wide access zones, and organized utilities.

Yes, they can be adapted for lifting, dredging, or piling operations.

Modularity, predictable stability, quick assembly, better safety, and integrated utilities.

Through integrated trays, clamps, and dedicated utility routes.

Yes, propulsion units can be integrated for maneuvering.