In a world with dwindling land availability and rising environmental challenges, floating construction platforms are now proving to be game-changing solutions. Floating platforms are not only engineering feats but are also providing sustainable, flexible, and affordable alternatives to conventional infrastructure. Floating wind farms, floating bridges, and modular houses - floating platforms are revolutionizing the way we construct and engage with it.

What Are Floating Construction Platforms?

Floating construction platforms are buoyant, designed structures that act as the foundation of construction in water bodies—rivers, lakes, reservoirs, seas, or flood-prone urban areas. They are meant to carry construction equipment, building material, and even full buildings.

Key Characteristics:

Buoyancy and stability

Modular and expandable

Eco-friendly materials

Weather- and corrosion-resistant designs

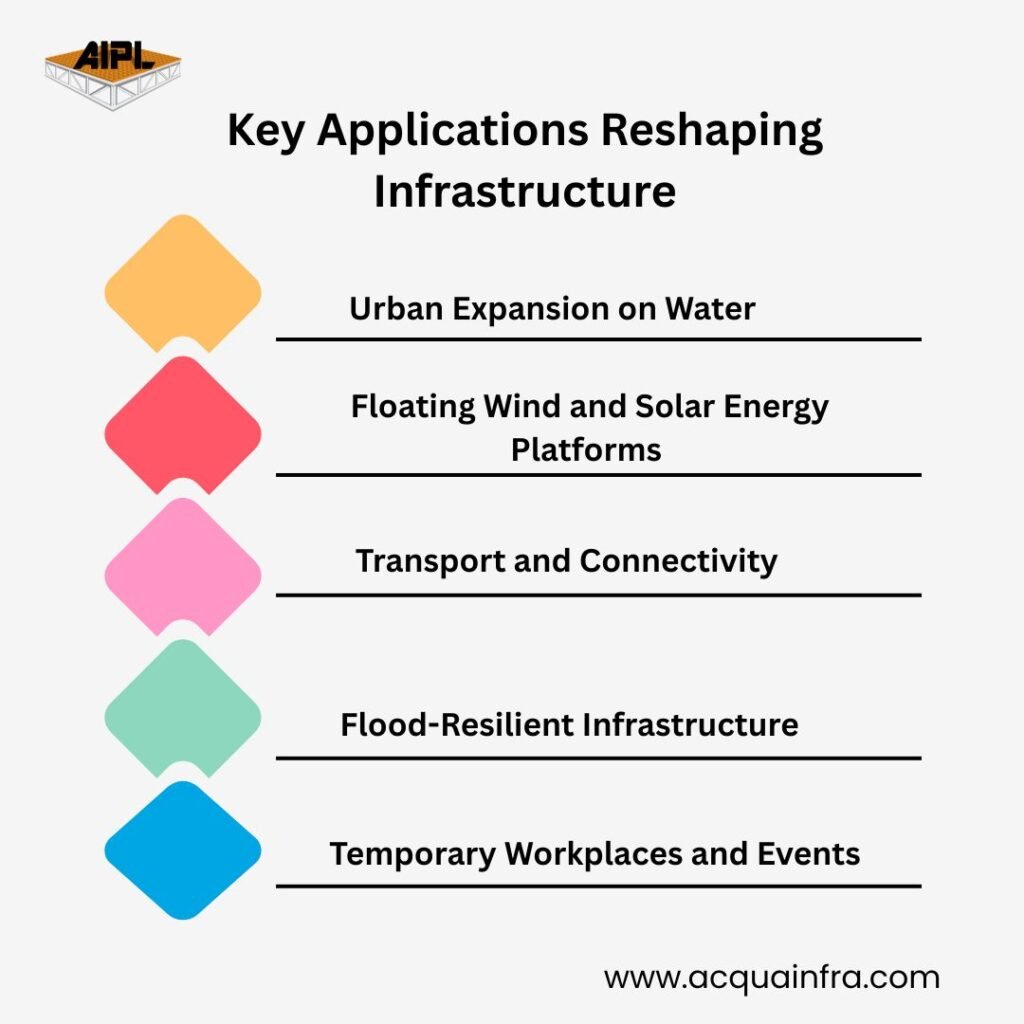

Key Applications Reshaping Infrastructure

1. Urban Expansion on Water

Amsterdam and Singapore are considering floating neighborhoods to address housing deficits without disrupting natural ground.

2. Floating Wind and Solar Energy Platforms

Sustainable energy installations are being placed on floating platforms, saving land while efficiently harnessing clean energy.

3. Transport and Connectivity

Pontoons and floating bridges are being utilized to enhance transport in regions with constrained access to land or periodic flooding.

4. Flood-Resilient Infrastructure

Flood areas are constructing schools, clinics, and shelters on floating platforms so that they remain accessible in times of need.

5. Temporary Workplaces and Events

From concert stages to oil rigs, floating platforms enable adaptable, mobile infrastructure that can be built and broken down on demand.

Advantages of Floating Construction Platforms

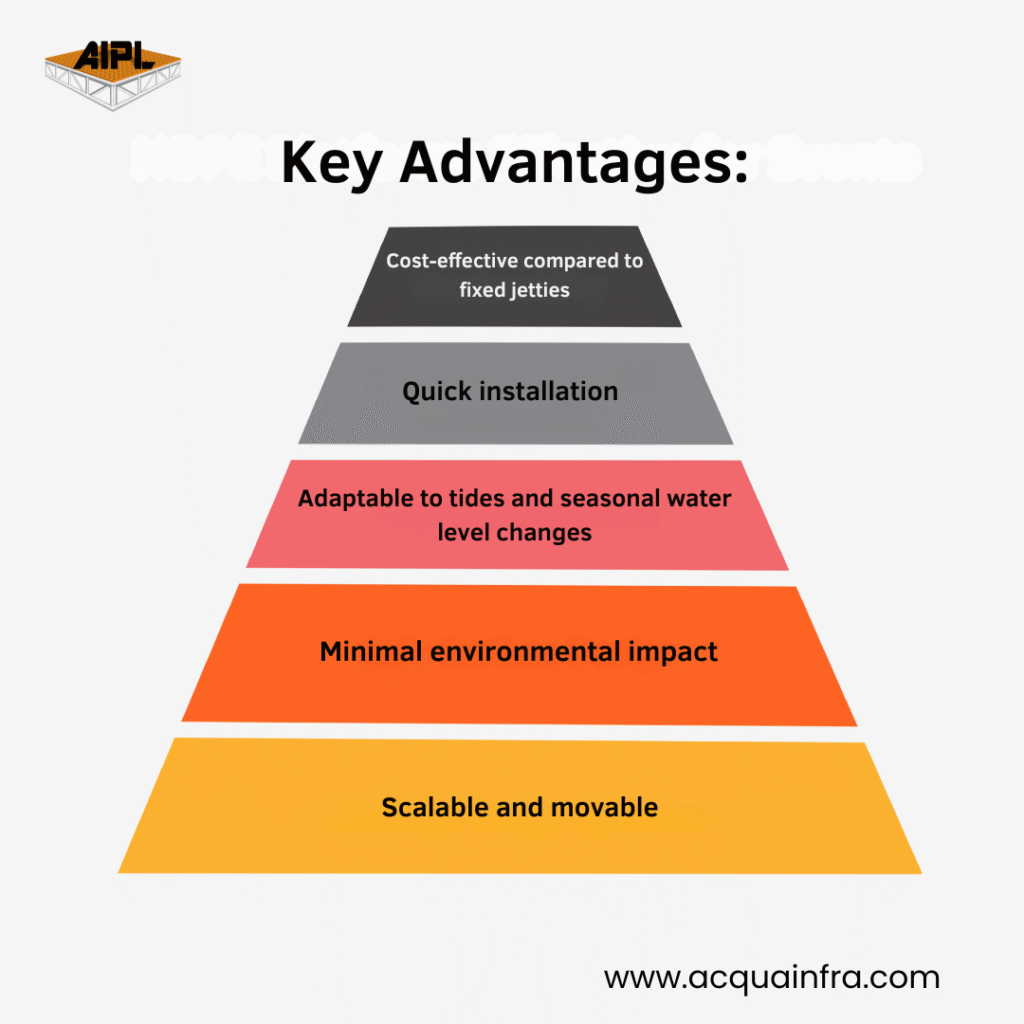

Land Conservation: Leverages water bodies, avoiding the need to reclaim or demolish valuable land.

Sustainability: Most platforms are built from recyclable material and cause minimal disruption to the environment.

Flexibility: Can be moved, altered, or expanded as required.

Cost Effectiveness: Economical foundation and excavation costs as compared to on-land construction.

Climate Change Adaptability: Floating platforms accommodate rising and falling water levels, making them highly suitable for flood areas and coastal cities.

Success Stories from the Real World

Netherlands: Pioneering floating city development, such as floating farms and residential communities.

Japan: Employing floating platforms for offshore airports and disaster relief shelters.

India: Utilizing floating solar farms on reservoirs and floating classrooms in flood zones.

How AIPL Assists With Floating Pump Pontoons

AIPL (Aquafront Infrastructure Projects Ltd.) has pioneered custom floating pump pontoons designed for:

Challenges and Innovations Ahead

While floating platforms offer immense potential, they face challenges such as:

Yet, continued innovation in marine engineering, intelligent anchoring systems, and AI-driven water monitoring is progressively overcoming these challenges.

FAQs

Q1. What is Acquafront Infrastructure Pvt. Ltd. (AIPL), and what does the company

specialize?

Acquafront Infrastructure Pvt. Ltd. (AIPL) is a pioneering company specializing in the

design, manufacturing, and installation of advanced floating infrastructure systems for

maritime and inland waterways. Since 2018, AIPL has been delivering IP-driven and

sustainable turnkey solutions tailored for sectors such as water supply, renewable energy,

tourism, dredging, defence, and transportation.

Q2. What types of floating structures does AIPL offer?

: AIPL offers four major types of modular floats tailored for diverse industrial

applications:

HDPE Cubes

MS Modular Barges

Steel Integrated Floating Jetty (SIFJ)

GFRC (Glass Fiber Reinforced Concrete) Floating Beams

Q3. Where are your corporate office and manufacturing facilities located?

Corporate Office:

3rd Floor, Tower-C, Office No. C-320, I-THUM, Plot No. A-40, Sector-62, Noida, Gautam

Buddha Nagar, Uttar Pradesh – 201301

Q4. Are your designs compliant with Indian standards or certified by third-party

institutions?

Yes, all our designs adhere to applicable Indian Standards such as IR-Class, IS 800, IS

456, IS 875, etc. Additionally, we support third-party design vetting through agencies like IR

Class, IITs, and Naval consultants as required.

Q5. Who are some of your key clients and past projects?

AIPL has delivered floating infrastructure solutions for prestigious clients such as:

Goa Shipyard Limited

GAIL

MECON

OIL India

VPRPL

ADHPL

OMPL

SPICEJET

PHED Odisha & Rajasthan

Conclusion: Building the Future on Water

Floating construction platforms are a bold move toward a more responsive, resilient, and sustainable future. They are no longer a concept for coastal engineers—they are becoming an important aspect of global infrastructure policy in a changing world.

Ready to ride the wave of innovation?

Whether you're a policymaker, builder, or eco-enthusiast, now is the time to explore how floating construction platforms can transform your projects and your community.

👉 Let's Connect! Reach out for consultations, collaborations, or customized floating solutions for your next big idea.

India, a country blessed with over 7,500 km of coastline and thousands of kilometers of navigable rivers, has immense untapped potential in water-based tourism. While traditional jetties served their purpose for decades, the modern age demands infrastructure that’s flexible, scalable, and eco-friendly — and this is where floating jetties are making a significant difference.

Floating jetties aren’t just infrastructure — they’re enablers of experiences, and India is finally embracing this shift.

A floating jetty (also called a floating pontoon) is a platform structure that floats on water, providing a stable landing and boarding point for boats, ferries, and other watercraft. Made using modular pontoons, reinforced plastics, or concrete structures, they’re anchored using chains or piles, adjusting naturally to changing water levels.

Key Advantages:

Tourism is evolving — travellers today seek unique, safe, and seamless experiences. Destinations with easy water access, adventure boating, cruises, and island hopping attract larger crowds. Unfortunately, India’s reliance on outdated fixed jetties often creates bottlenecks.

Floating jetties solve this problem by:

Example:

Goa’s floating jetties at Britona and Panaji have significantly improved tourist access to inland water cruises and riverfront dining.

Recognizing their utility, the Ministry of Ports, Shipping and Waterways (MoPSW) is actively promoting floating jetties under the Sagarmala Programme. Notable projects include:

✔️ Seamless Tourist Experience:

Visitors enjoy hassle-free boarding without worrying about tides or slippery, old docks.

✔️ Eco-Friendly Infrastructure:

Floating jetties cause minimal disruption to the aquatic ecosystem compared to permanent piers.

✔️ Boost to Local Economy:

Adventure sports operators, boat rental businesses, and riverside vendors benefit from improved facilities.

✔️ Better Safety and Accessibility:

Ideal for the elderly, differently-abled, and children due to sturdy, anti-slip surfaces.

✔️ Seasonal Flexibility:

Temporary or movable jetties cater to seasonal tourist peaks without heavy infrastructure investment.

As India’s leading turnkey provider of floating infrastructure solutions, AIPL (Acquafront Infrastructure Pvt. Ltd.) is playing a pivotal role in advancing water-based tourism.

Services AIPL Offers:

Why Choose AIPL?

If you’re a resort, marina, or state tourism body seeking to enhance your water access infrastructure — AIPL has the expertise to deliver world-class solutions.

Contact AIPL Today to Plan Your Floating Tourism Project.

Q1. What is a floating jetty used for?

A floating jetty provides a stable, water-level-adaptive platform for boarding, mooring boats, or recreational purposes in water-based locations.

Q2. How are floating jetties eco-friendly?

They cause minimal disruption to the aquatic ecosystem and can be easily removed or relocated without permanent structural changes to water bodies.

Q3. How much does it cost to install a floating jetty in India?

Costs vary based on location, size, materials, and load capacity. Contact AIPL for a customized quotation.

Q4. Are these safe for tourists?

Yes. They’re designed with anti-slip surfaces, railings, and are anchored securely, making them safe for families, children, and elderly passengers.

Q5. What are some popular tourist spots in India using floating jetties?

Goa, Kerala backwaters, Daman-Diu, Chilika Lake, and Sundarbans are actively using floating jetties for tourism enhancement.

Imagine your brand message floating majestically on the Ganges in Banaras, gliding past tourists on Mumbai’s beaches, or catching thousands of eyes over Bhopal’s lakes. Sounds like a dream? Welcome to the world of floating advertising platforms—a revolutionary way to captivate audiences where they least expect it: on water.

In this blog, we explore how floating platforms are transforming advertising, highlight real-world examples, and showcase the innovative SIFJ (Steel-Integrated Floating Jetty) by Aquafront Infrastructure Pvt. Ltd. (AIPL), and show you how you can leverage this powerful medium for your brand.

Let’s keep it simple. Floating advertising platforms are structures installed on water bodies—lakes, rivers, seas—that act as mobile or stationary billboards. Think of them as giant, floating canvases for your brand message.

👉 Whether it’s a static installation or a moving display, these platforms offer unmissable visibility, especially in tourist hotspots, waterfront venues, or high-traffic water routes.

A few years ago, cricket fans and beachgoers at Juhu were stunned to see a giant floating billboard for Mumbai Indians, right in the sea! The campaign made headlines, sparked conversations, and became a perfect example of how brands can break the clutter by advertising on water.

While Bhopal is famous for its lakes, its potential for floating ads is still underexplored. Imagine a floating platform promoting a tourism festival or a beverage brand right in the middle of Upper Lake. A few pilot projects have sparked curiosity, signaling a huge opportunity for brands willing to experiment.

In Varanasi, AIPL installed floating CNG stations at Ravidas Ghat and Namo Ghat. Beyond their functional role, these installations have opened up possibilities for eco-friendly branding and public awareness campaigns along the iconic Ganges.

🔗 Learn more about AIPL projects

At the heart of this advertising revolution is technology, and AIPL’s Steel-Integrated Floating Jetty (SIFJ) is leading the charge.

Unlike inflatable or temporary structures, SIFJ is a permanent, modular, high-strength floating dock system designed for diverse applications—from events and tourism to advertising and construction.

| ✅ Feature | 🚩 What It Means for You |

| Modular Design | Flexible sizes (6m x 3m, 6m x 2.5m) to fit your campaign vision |

| Steel-Composite Build | Durability you can count on—weather, wear, and tear-resistant |

| Certified Quality | Approved by IRS, IIT, CIPET, NABL—peace of mind guaranteed |

| Versatile Applications | From advertising to events, energy, pumping stations, and more |

| Custom Branding | Tailored surface designs to make your brand shine |

Learn more about SIFJ here → AIPL SIFJ Product Page

Here’s what makes floating advertising a next-gen marketing tool:

Unavoidable Visibility: It’s hard to ignore a message that’s literally floating in your line of sight.

Captive Audience: Whether it’s tourists on a boat ride, pilgrims on a ghat, or commuters near a lake—floating ads are designed for places with captive, leisurely audiences.

Photo-Worthy & Shareable: Floating ads are inherently “Instagrammable”. Expect people to take photos and share them online, giving you organic reach.

Eco-Friendly Options: With products like SIFJ, brands can use non-invasive, sustainable platforms that don’t disrupt aquatic life.

Q1. What is Acquafront Infrastructure Pvt. Ltd. (AIPL), and what does the company

specialize?

Acquafront Infrastructure Pvt. Ltd. (AIPL) is a pioneering company specializing in the

design, manufacturing, and installation of advanced floating infrastructure systems for

maritime and inland waterways. Since 2018, AIPL has been delivering IP-driven and

sustainable turnkey solutions tailored for sectors such as water supply, renewable energy,

tourism, dredging, defence, and transportation.

Q2. What types of floating structures does AIPL offer?

AIPL offers four major types of modular floats tailored for diverse industrial

applications:

HDPE Cubes

MS Modular Barges

Steel Integrated Floating Jetty (SIFJ)

GFRC (Glass Fiber Reinforced Concrete) Floating Beams

Q3. Where are your corporate office and manufacturing facilities located?

Corporate Office:

3rd Floor, Tower-C, Office No. C-320, I-THUM, Plot No. A-40, Sector-62, Noida, Gautam

Buddha Nagar, Uttar Pradesh – 201301

Manufacturing Facility:

Acquafront Infrastructure, Rania Industrial Area, Kanpur, Uttar Pradesh – 209101

Q4. Are your designs compliant with Indian standards or certified by third-party

institutions?

: Yes, all our designs adhere to applicable Indian Standards such as IR-Class, IS 800, IS

456, IS 875, etc. Additionally, we support third-party design vetting through agencies like IR

Class, IITs, and Naval consultants as required.

If you’re thinking:

👉 “This sounds cool, but how do I make it happen?”

Here’s where Aquafront Infrastructure Pvt. Ltd. (AIPL) steps in.

Turnkey Solutions: From design to installation to maintenance, AIPL handles it all.

Custom Designs: Your campaign, your platform—AIPL builds it tailored to your vision.

Proven Track Record: With projects like floating CNG stations, modular jetties, and marine infrastructure across India, you’re in expert hands.

Whether you’re a sports brand, tourism board, beverage company, or event organizer, floating platforms offer a once-in-a-blue-moon opportunity to wow your audience.

👉 Contact AIPL Today:

🌐 Website: www.acquainfra.com

📧 Email: admin@acquainfra.com

📞 Call: +91-7678232371

👉 Or explore their full range of floating solutions here: Product Portfolio

In a world overloaded with ads, sometimes the best way to stand out is to step off the land.

With floating advertising platforms, brands get a chance to own unique, untapped spaces, captivate audiences in scenic environments, and leave a lasting impression.

With AIPL’s expertise and innovative products like SIFJ, your brand won’t just float—it will command attention.

Looking for creative, sustainable, and high-impact advertising? Let’s get your brand floating Contact Us today.

Floating structures, such as pontoons, jetties, and floating walkways, are revolutionizing infrastructure in water-dominated geographies. Yet, beneath their innovative design lies an essential requirement: regular maintenance to ensure operational safety, longevity, and performance. For organizations like Acqua Infra, Annual Maintenance Contracts (AMC) are not just a service—they’re a strategic safeguard for critical infrastructure, especially in flood-prone areas.

High mechanical load during peak usage

Without proper maintenance, minor defects can quickly escalate into:

In regions where floating structures support essential services—like rescue operations, flood management, or community access—their reliability can literally save lives.

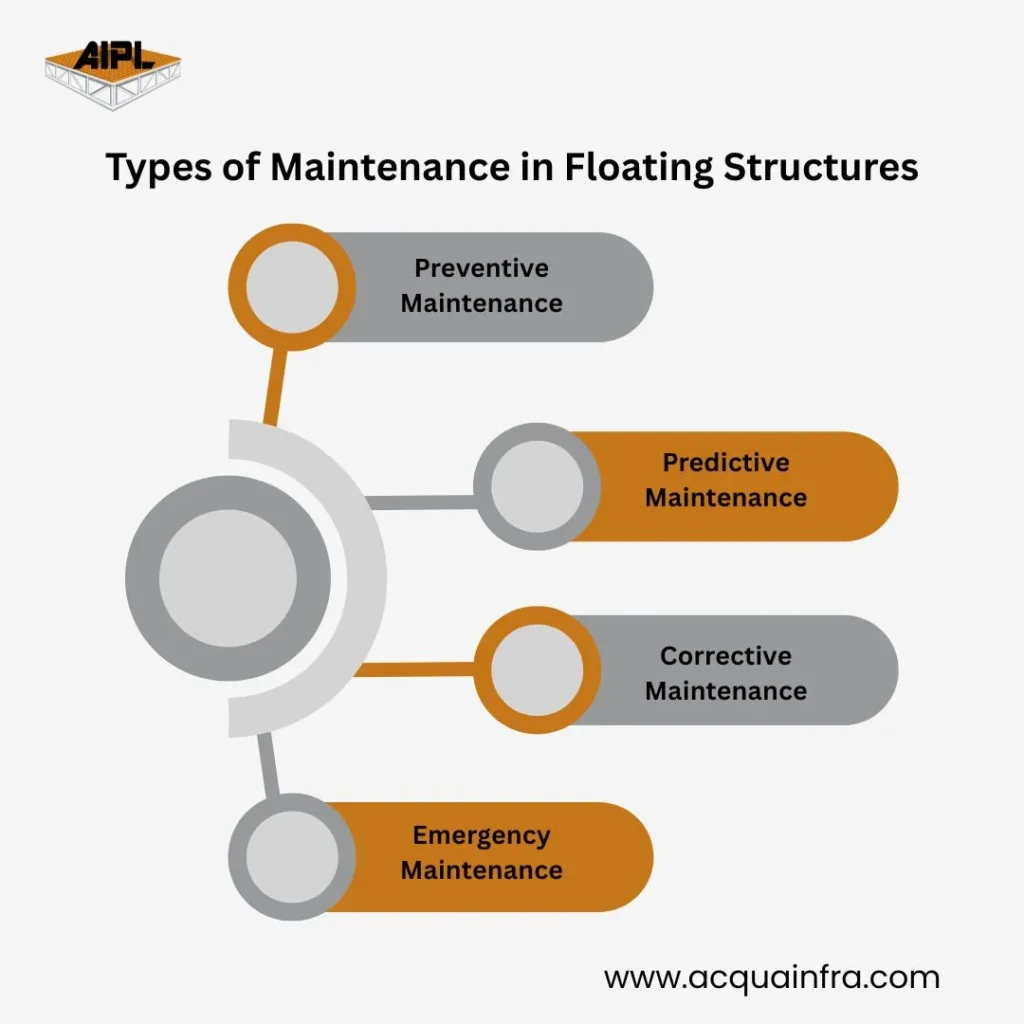

Maintenance for floating pontoons and similar infrastructure falls under four broad categories:

Preventive Maintenance

Regularly scheduled inspections and minor repairs to avoid larger failures. Includes cleaning, lubrication, coating checks, and inspection of joints.

Predictive Maintenance

Use of monitoring technologies (strain gauges, corrosion sensors, ultrasonic testing) to predict component failure before it occurs.

Corrective Maintenance

Reactive maintenance performed after a defect is detected, to restore full operational condition.

Emergency Maintenance

Immediate interventions during unexpected failures or adverse conditions like floods, storms, or anchor drift.

For clients under AMC with AcquaInfra, a hybrid model combining preventive, predictive, and corrective maintenance ensures proactive infrastructure management.

Maintaining Anchor Position: The Hidden Backbone

Anchors are critical to the stability of floating structures. Over time, anchor lines and mooring chains are subject to:

Regular maintenance involves:

Anchor failure can result in pontoon displacement, collisions with nearby structures, or complete detachment—a risk that AMC programs mitigate with scheduled checks.

Floating structures often incorporate critical equipment such as:

Equipment maintenance involves:

AIPL’s AMC plans ensure that every equipment component works seamlessly, even under stress conditions.

Case Study:AIPL holds AMC for the maintenance and operational support of the floating CNG station infrastructure.

Floating CNG Station for GAIL (India) Ltd. – Varanasi

We have successfully designed, supplied, and installed a 324 square meter Floating CNG Station at Namo Ghat, Varanasi, for GAIL (India) Ltd. This floating station has been developed to facilitate the dispensing of Compressed Natural Gas (CNG) to inland boats operating along the Ganga river. The station was commissioned in December 2021 and marks a significant step toward green energy adoption in inland waterways.

This infrastructure has been developed using our in-house Mild Steel Modular Pontoons and Steel Integrated Floating Jetty (SIFJ) systems. These modular, scalable, and robust platforms are designed to withstand seasonal variations in water levels and provide a stable base for CNG dispensing operations.

We hold a 5-year AMC contract for the maintenance of the floating CNG station infrastructure. The AMC scope includes the following key responsibilities:

This initiative is a model for sustainable water-based infrastructure and demonstrates the scalability and utility of modular floating solutions in supporting eco-friendly energy distribution on rivers and inland waterways.

Why Choose AMC from AIPL for Floating Structures?

Investing in an AMC for floating structures isn’t an expense—it’s an assurance of safety, reliability, and performance. With proven expertise in maintaining pontoons and critical floating infrastructure under even the harshest conditions, AIPL’s AMC solutions empower clients to focus on operations while their assets stay protected and functional.

To explore AMC packages tailored for your floating infrastructure needs, visit acquainfra.com or connect with an AIPL representative today.

An AMC typically covers:

Regular inspections of pontoons, joints, and floatation modules

Cleaning and anti-corrosion treatments

Maintenance of anchoring and mooring systems

Equipment servicing (lighting, pumps, electrical components)

Structural integrity checks

Emergency repairs and priority support

At Acqua Infra, the AMC can be customized based on structure size, usage, and location.

Corrode

Stretch or weaken

Drift from their original position due to shifting seabeds

Regular maintenance ensures:

Stability and safety of the pontoon

Compliance with maritime regulations

Prevention of costly anchor failure or pontoon displacement

Inspection frequency depends on environmental exposure and usage intensity. Typically:

Routine inspections: every 3-6 months

Post-extreme weather inspections: immediately after storms, floods, or high currents

Annual comprehensive audits: once a year

Acqua Infra tailors inspection schedules based on site conditions and client needs.

If a serious defect or safety hazard is identified:

Immediate reporting to the client

Recommendation of corrective action

Emergency repair or reinforcement (if under AMC coverage)

Option to upgrade or retrofit the structure if needed

With AMC, clients get priority servicing and cost-effective repair options.

Absolutely! Acqua Infra provides custom AMC packages for specialized floating assets, including:

Solar power platforms

Walkways and bridges

Fuel stations

Hospitality venues

Each contract is designed considering the unique materials, load, and environmental exposure of the structure.

Ready to Safeguard Your Floating Infrastructure?

Partner with AcquaInfra Projects Limited for reliable, expert-led AMC solutions that keep your floating structures safe, compliant, and operational—365 days a year.

👉 Visit acquainfra.com or contact us today to learn more.

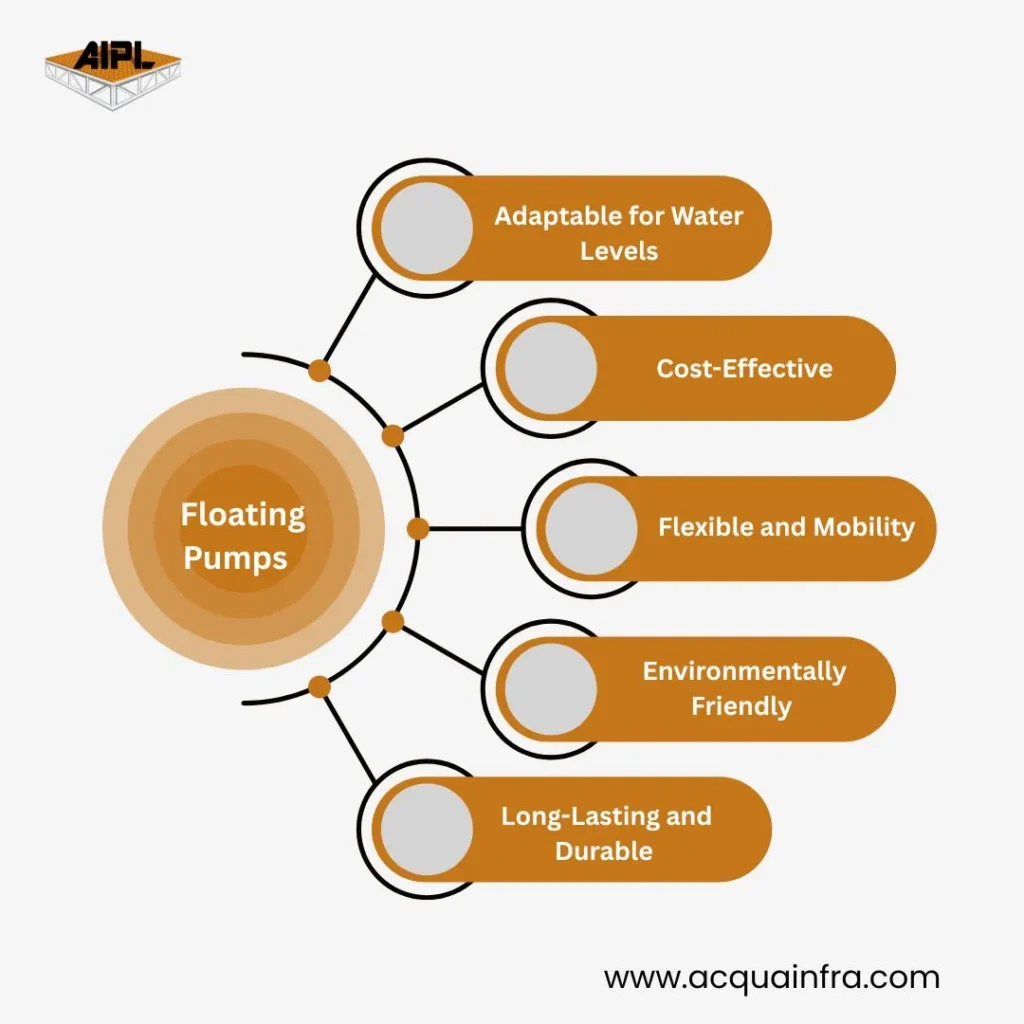

Imagine the possibilities of obtaining the water you require from rivers, lakes and reservoirs with a minimal infrastructure expenditure. This sounds fantastic isn't it? That's exactly the reason floating Pump Pontoons enter their role! Beautiful floating structures are a practical and easy solution for water supply industries and the need to drain water. Let's examine how floating pontoons to pump water have revolutionized the field based on actual needs, human thinking and practical applications.

A floating pontoon pump actively supports pumps and connected equipment directly on the water by using an inflatable structure designed for buoyancy and stability. It allows efficient water intake and the removal of water from the water's surface. This guarantees stability, flexibility, and optimum performance, even in the midst of fluctuating water levels or under difficult conditions.

Instead of spending a lot of money on fixed structures, businesses can simply put up floating pontoons, place the pumping device onto it and then begin operation immediately.

The fundamental idea is:

Modular elements form a solid floating platform over the water. The team securely positions pumps and pipes onto the pontoon. Anchors or mooring systems hold it in place to prevent drifting.

Pumps take water directly from the source, and provide the capability to adjust to changing or rising levels of water.

This arrangement allows for continuous drainage and water dewatering with no typical hurdles associated with land, such as erosion, silting or floods that occur during the season.

Water bodies change depending on the time of year. Pontoons floating on the water naturally increase and decrease according to the fluctuation of levels of the water, keeping the pumps at their optimal level without requiring constant adjustments.

Permanent pumping stations, or docks can be extremely expensive. Floating pontoons can be a fantastic option to save money.

Are you planning to move the equipment you have? Absolutely not any problem! Pump pontoons floating on water can be easily moved and easily, which makes them perfect for projects which require agility and speed.

There is minimal disturbance to the ecological balance. There is no requirement for altering the land.

With the use of corrosion-resistant materials, floating pontoons are able to stand up to severe environmental pressures for a number of years.

The name says it all: AIPL . We do more than just make pontoons- we provide creative floating services that can be adapted to each customer's needs. Our team makes use of top-quality materials and innovative designs and tried anchoring systems which have been tested in the field to ensure that your floating pump's pontoon will be able to work flawlessly in any conditions.

Designs that are customized to meet the various capabilities of pump

Quick deployment and easy relocation

Assistance after sale and maintenance

With a focus on safety, stability as well as long-term durability

If you're looking to find a reliable partner in water management or dewatering requirements, AIPL is eager to assist you in reaching your goals!

Yes! Modular pontoons may be designed to house pumps of various capacities, ranging from small irrigation pumps to huge industrial systems.

It's not. AIPL provides complete support throughout installation to ensure a simple and seamless installation.

Made of high-end materials like UV stabilized HDPE and aluminum, the pontoons can last 15 years or more if they are maintained provided they are maintained correctly.

Absolutely. This is among the most significant benefits - they automatically adapt to changes in the levels of the water.

Looking to boost your water supply or dewatering operations? Let AIPL’s floating pump pontoons lead the way!

🚀 Contact us today for customized floating solutions that guarantee performance, durability, and peace of mind.

Mining and cement industries require a consistent and reliable water supply for their operations. Whether it’s for mineral processing, dust suppression, or slurry transportation, managing water efficiently is crucial.

Floating Pumping Stations offer a smart, flexible, and cost-effective solution for these sectors.

At AcquaInfra, we specialize in providing custom-engineered floating pumping systems that meet the demanding needs of mining and cement factories.

Floating pumping stations are floating platforms equipped with water pumps, designed to operate directly on lakes, rivers, or reservoirs. Unlike traditional intake wells, they don’t require heavy civil construction and can adjust to varying water levels. These stations are ideal for remote, flood-prone, or hard-to-reach locations, offering flexibility, faster installation, and cost-effectiveness.

1. Access to Remote or Inaccessible Water Sources

Mining and cement operations often take place in challenging terrains. Floating pumping stations allow easy access to reservoirs, pits, or ponds where fixed infrastructure is not feasible.

2. Adaptability to Changing Water Levels

Unlike traditional setups, floating pumps automatically adjust to fluctuating water levels, ensuring consistent operation during monsoons, droughts, or site changes.

3. Reduced Civil Infrastructure Costs

They eliminate the need for building costly pump houses, pipelines, or foundations. This makes deployment faster and more economical, especially in temporary or evolving project sites.

4. Durable in Harsh Conditions

Designed for Extremes – Built to withstand high temperatures, heavy rainfall, and strong currents.

Resilient Materials – Made from high-grade HDPE and treated steel for long-term durability.

Low Wear & Tear – Engineered for minimal maintenance even in challenging environments.

Reliable Year-Round – Operates efficiently in both dry and flood-prone conditions.

Engineered for Longevity – Crafted to perform reliably over years, despite rough usage or weather.

5. Portable and Easy to Relocate

Floating pumping stations are modular and movable. This makes them ideal for phased projects or sites where pumping needs change over time.

6. Eco-Friendly and Energy-Efficient Options

Floating pumping stations offer an eco-conscious solution to modern water infrastructure challenges. Designed using sustainable and often recyclable materials, they leave a reduced environmental footprint compared to traditional systems. Their floating nature ensures minimal disruption to aquatic ecosystems, preserving biodiversity while delivering efficient water supply.

Where Floating Pumping Stations Are Used

| Application Area | Purpose |

| Open-pit mining | Dewatering operations |

| Mineral processing plants | Water supply for crushing and processing |

| Cement factories | Process water, dust suppression, and cooling |

| Tailings ponds | Recycling process water |

| Slurry transportation | Moving slurry from pits to processing plants |

1. Corrosion-Resistant Platforms

These materials ensure long-term durability in harsh water environments, reducing maintenance needs and extending the life of the platform—even in saline or chemically impacted water bodies. This ensures durability and a long operational life, even in harsh environmental conditions such as saline water or chemically reactive industrial ponds.

2. Heavy-Duty Pumps Suitable for Abrasive Fluids

These systems are equipped with industrial-grade pumps designed to handle abrasive and high-solid-content fluids. Ideal for mining slurries and cement process water, they maintain efficient operation without frequent wear or failure.

3. Solar Electric or Diesel-Powered Options

Depending on site requirements, renewable solar energy powers the floating pumps for sustainability, or diesel engines power them for remote and high-power applications. This flexibility supports off-grid operations while reducing fuel dependency.

4. Easy Maintenance Access

The platform layout allows technicians to easily access critical components for inspections and repairs. Guardrails, safe walkways, and tool-friendly setups enhance safety and efficiency during maintenance.

5. Quick Installation and Dismantling

Designed for mobility and modularity, these systems can be swiftly installed or dismantled without requiring heavy civil works. This makes them ideal for both temporary and long-term industrial use.

6. Cost Effectiveness

AcquaInfra's floating pumping stations reduce the need for permanent civil structures like platforms or foundations. This significantly lowers installation and maintenance costs, making it a budget-friendly solution for mining and cement industries.

7. Easy Transportation

The modular and lightweight design of our systems allows for quick assembly, disassembly, and relocation.

At Acqua Infra Projects India Ltd. (APIL), we offer customized floating pumping station solutions designed to meet the tough demands of the mining and cement industries. Our systems are engineered to provide efficient water and slurry handling in remote and fluctuating environments where traditional pumping infrastructure may fall short.

Whether operating in open-pit mines or cement processing units, AIPL’s floating pumping stations ensure uninterrupted water supply and slurry transport, improving productivity and operational sustainability.

Yes. We design our systems with heavy-duty pumps that are abrasion-resistant, perfect for dirty water, slurries, or sediment-heavy fluids.

Yes, floating pumping stations are designed for long-term safety and reliability. Built with durable, weather-resistant materials, they can withstand harsh environmental conditions. With proper maintenance, they offer consistent performance and structural integrity for years, making them a secure solution for long-term water infrastructure needs.

Installation is fast and typically much quicker than traditional fixed pumping stations, depending on the project size and location.

Yes, our floating pumping systems are fully customizable to meet the specific requirements of cement production processes.

Minimal maintenance is needed thanks to easy access designs and durable components.

Our floating pumping stations are engineered for reliability, efficiency, and savings.

Get in touch with our experts today and find the perfect solution for your project.

In a place like India in which water is plentiful and in short supply based on climate and geography, having a strong infrastructure for water is vital. The traditional intake wells served as extraction of water, however as the terrain changes and water levels as well as accessibility, floating pumping stations are gaining popularity as an efficient and flexible solution. This blog focuses on the differentiators between the advantages, benefits, and transformational capabilities in floating pumping stations as compared to conventional intake wells and in particular an environment of rising demand for water.

Intake wells are a fixed structure that are built on the banks of reservoirs or rivers to draw water by pumps or gravity. Although historically stable, intake wells have to face issues like

Floating pumping stations, usually installed upon floating pontoons that are modular, are mobile platforms equipped with pumps that sit right on top of the body. They move according to the water level, which ensures constant access to the source of water.

They're typically equipped with:

| Feature | Intake Wells | Floating Pumping Stations |

| Installation Cost | High | Moderate |

| Flexibility | Rigid | Highly versatile |

| Maintenance | Labor-intensive | Easier & cost-effective |

| Water Level Adaptation | Poor | Excellent |

| Remote Area Access | Limited | Great for remote sites |

| Seasonal Movement | Unrealistic | Reposition easily |

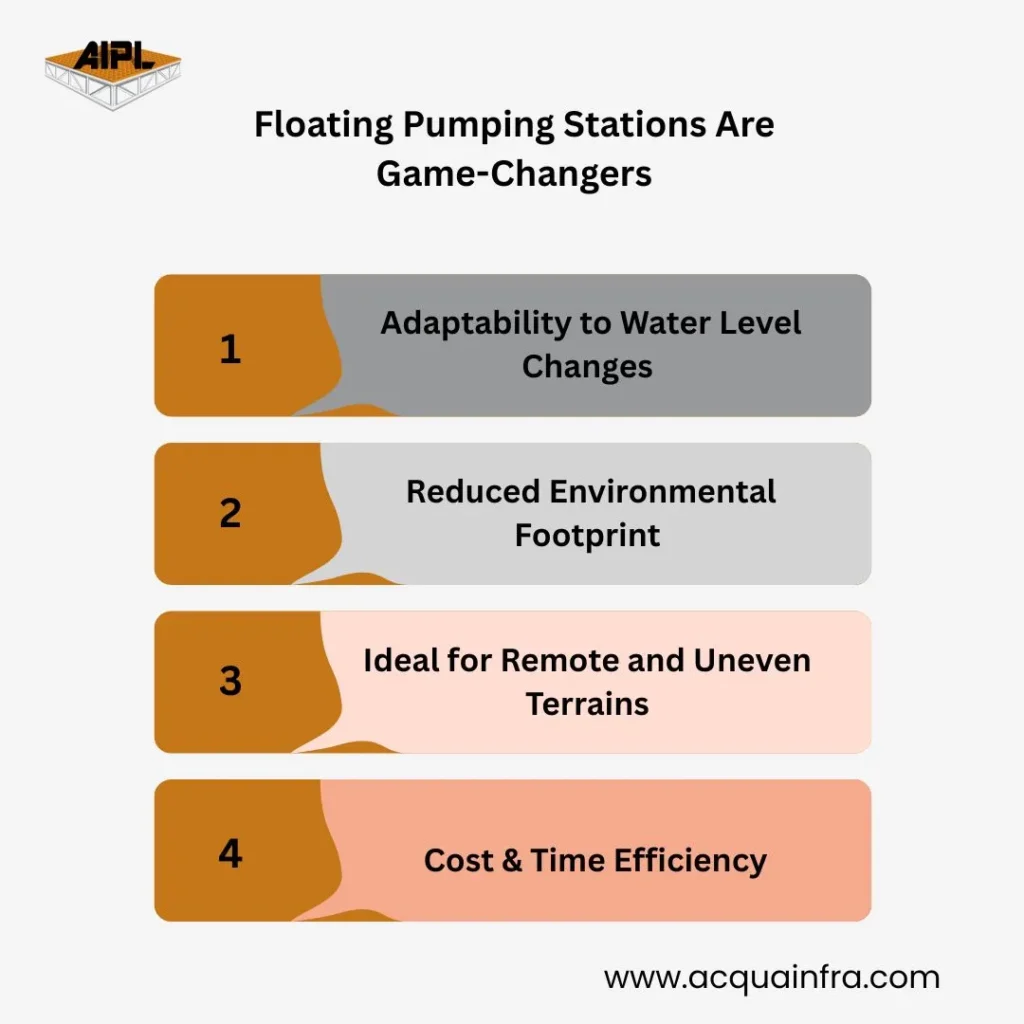

1. Adaptability to Water Level Changes

As opposed to intake wells, floating pumps remain in place regardless of the fluctuations in water. This allows for uninterrupted operation in floods or drought.

Floating pump pontoons reduce environmental impact by minimizing land use and avoiding major civil construction near water bodies.

In areas that are marshy or hilly the construction of intake wells is virtually impossible. Floating pontoons are a solution efficiently.

The stations are prefabricated and modular making construction much faster and requiring less capital investment.

AcquaInfra Projects Pvt. Ltd. (AIPL) is a specialist in constructing and delivering custom floating pumping stations, which include:

With AIPL water access, it becomes efficient, scalable and intelligent.

Floating pumping stations adapt to changing water levels and are easy to maintain, making them more versatile than intake wells.

Yes, they are ideal for both small and large-scale water infrastructure, including government and industrial projects.

Installing a floating pumping station typically takes 7 to 15 days for small to medium projects, and up to 30 days for larger ones. The process includes site prep, assembling modular pontoons, anchoring, connecting power and pipes, and final testing. With expert support like AIPL, installation is faster and more efficient than traditional methods.

Yes, floating pump pontoons require minimal but regular maintenance, including checking for debris, inspecting anchors, and servicing pumps to ensure smooth operation and longevity.

Yes, AIPL specializes in installing floating pump pontoons in flood-prone and remote areas, ensuring efficient water management even in challenging terrains.

Need a Smart Water Supply Solution?

Get in touch with AquaInfra Projects Pvt. Ltd. (AIPL) today to explore how our Floating Pumping Stations can revolutionize your project.

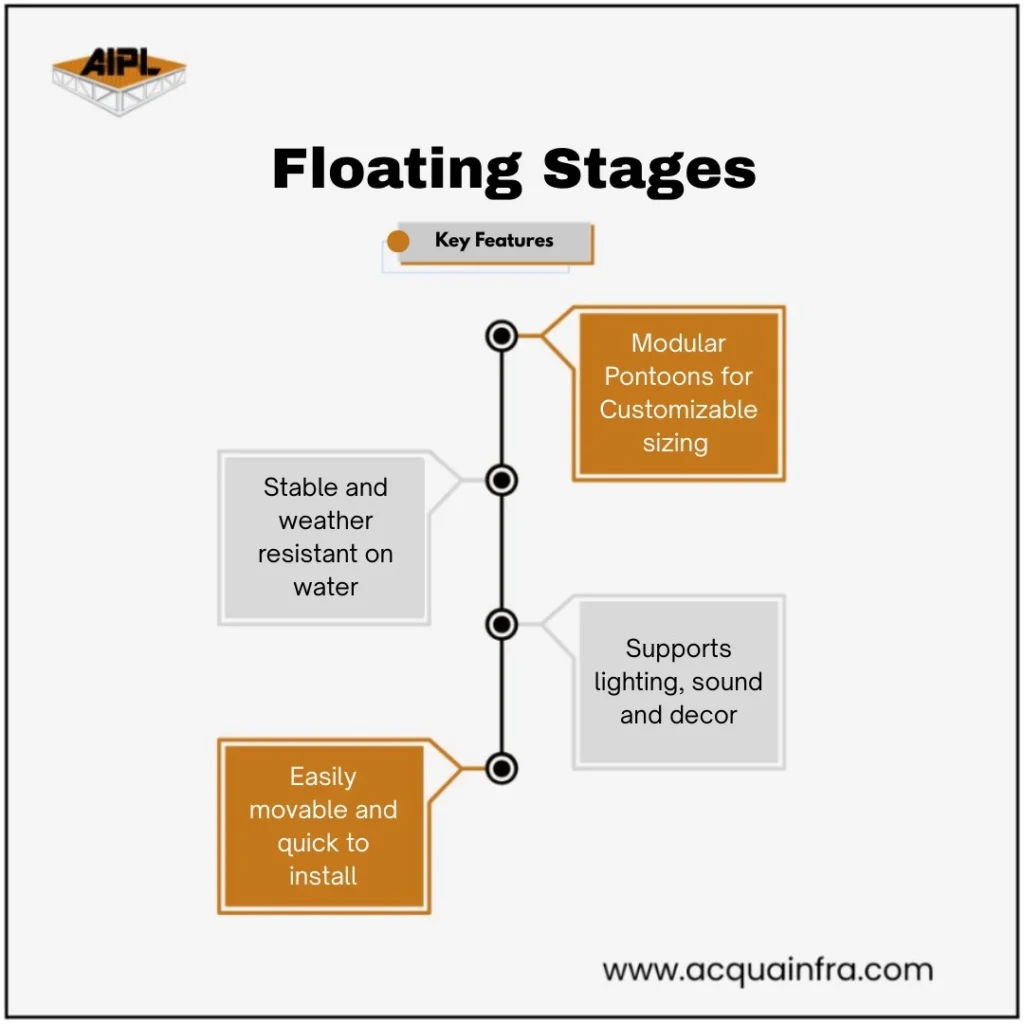

Imagine that you're listening live to music while you float on platforms suspended in the sky, enjoying the gentle sound of the water all over you. It's not only a dream. That's the attraction of floating stages that is an increasingly popular trend in the tourism and hospitality industry. In this article we'll explore the benefits of floating stages and their cons and pros in terms of design, real scenarios, and the ways that organizations like AIPL have helped to create memorable water-based events.

An inflatable stage, also known as a floating platform is a modular stage constructed on water and specifically designed for weddings, concerts, and many other occasions. These structures can be positioned to shores, lakes, rivers or the shores of the sea. They are becoming an essential element in luxurious tourism and the development of waterfronts.

Unique Experiences: Floating stages offer unique events that invite guests to, changing an ordinary occasion into an extravagant occasion.

Location Freedom: They are often set up in the riverbanks, along lakesides, and in hotels. They are great for weddings that don't follow tradition, or for concerts that are held outdoors.

Eco-Friendly Design: Modern designs are eco-friendly and incorporate green products and lighting powered by solar systems that conform to the most recent developments in sustainable tourism.

Flexibility & Portability: They can be assembled quickly and moved from one site to another—making them a favorite for tourism departments and event organizers.

Design and Technical Aspects:

Advanced Infrastructure. Ltd. (AIPL) AIPL is a pioneer in the design of customized floating systems that incorporate sustainability, design for safety as well as safety.

Yes, they're designed to be secure, and they're built on a proper anchoring system and load distribution.

Yes! These stages are ideal for weddings, music nights and product launch events and cultural celebrations.

The permissions are different in accordance with the state and water bodies. AIPL assists in coordination with authorities.

They're not. They are modular and mobile, making them perfect for temporary or seasonal installations.

It's true, if you've got the proper materials and designs, they're appropriate for freshwater and coastal environments.

🎤 Host Your Next Event on Water – In Style!

Transform ordinary gatherings into extraordinary experiences with AIPL’s Floating Stage Solutions. Whether it’s a concert, wedding, or VIP event, our customizable, stable, and elegant floating platforms deliver luxury and impact on any waterbody.

👉 Contact AcquaInfra Today to bring your dream event to life on water.

The Kumbh Mela is held every 12 years at each of the four locations: Prayagraj (Allahabad), Haridwar, Nashik, and Ujjain India, is renowned as the world's largest religious gathering. In 2025, the event witnessed a significant infrastructural innovation: the introduction of the "Floating Kund."

This Floating Kund at Mahakumbh was designed to enhance the bathing experience for pilgrims, particularly VIPs, by providing a safe, comfortable, and private space for the ritualistic dip at the sacred confluence of the Ganga, Yamuna, and the mythical Saraswati rivers.

Source: The Story Mug

Key Benefits

Source: NDTV

| Feature | Description |

| Propulsion | Self-propelled mechanism for mobility |

| Capacity | Accommodates up to 5 individuals simultaneously |

| Safety Measures | Deep-water barricading and safety nets |

| Amenities | Seating, changing rooms with mirrors, solar lights |

| Construction Material | Durable, water-resistant materials |

Source: The Hawk

The Floating Kund at Mahakumbh was lauded for its innovative approach to managing the massive influx of pilgrims while ensuring safety and comfort. It set a precedent for integrating modern technology into traditional religious practices, offering insights into managing large-scale events with infrastructural innovations.

Source: New Kerala

Q1: What is the primary purpose of the Floating Kund?

A: To provide a safe, comfortable, and private bathing experience for VIP pilgrims during the Maha Kumbh Mela.

Q2: Who developed and constructed the Floating Kund?

A: It was developed by IIT Kharagpur and constructed by Das & Kumar Company, Varanasi.

Q3: How does the Floating Kund ensure safety?

A: Through deep-water barricading, safety nets, and controlled access to prevent overcrowding.

Q4: Is the Floating Kund eco-friendly?

A: Yes, it utilizes solar-powered lighting, reducing environmental impact.

Q5: Can the Floating Kund model be replicated elsewhere?

A: Absolutely. Its design offers a blueprint for integrating modern infrastructure into large-scale religious or public events.

The introduction of the Floating Kund at Maha Kumbh 2025 exemplifies how traditional events can embrace modern innovations to enhance participant experience. By prioritizing safety, comfort, and sustainability, it offers a model for future large-scale gatherings worldwide.

For more insights into infrastructural innovations and case studies, visit AcquaInfra. If you're interested in implementing similar solutions for your projects, feel free to contact us.

With growing urbanization and shrinking land availability, the world is looking toward smarter ways to harness the sun. That’s where floating solar steps in — a revolutionary concept where solar panels float over water bodies like reservoirs, lakes, and dams, generating clean energy without occupying precious land.

Floatovoltaics or floating solar is installing photovoltaic (PV) panels on the surface of still water bodies. The platforms are designed to be light in weight but highly durable, made from UV-stable HDPE material, and securely anchored so that they won't drift. Power produced from these panels is fed to the shore and to the grid as with land solar farms.

Floating solar (also known as floatovoltaics) refers to solar panels installed on floating platforms over water bodies like reservoirs, lakes, and dams.

Instead of occupying large tracts of land, these panels sit on buoyant, modular structures that harness solar power efficiently while reducing land use.

No Land Use Conflicts

Utilizes unused water surfaces - ideal for countries with land scarcity.

Higher Efficiency

Water keeps the panels cooler, improving performance up to 10-15%.

Reduces Water Evaporation

Perfect for reservoirs and irrigation tanks in dry areas.

Environmentally Friendly

Reduces carbon footprint, protects aquatic ecosystems from overheating.

Scalable & Modular

Can be designed for small ponds or large industrial reservoirs.

At the global level, China, Japan and the Netherlands are leading the charge with large-scale floating solar deployments. China is ahead with more than 1.5 GW of capacity, but India is charging ahead with major projects in Kerala, Telangana and West Bengal. India alone is planning 10 GW of floating solar capacity by 2030 — and that's a huge opportunity for clean-tech players and infrastructure providers.

This leads us to how AIPL (Acqua Infra Projects Pvt. Ltd.) is actually making a difference. AIPL is in the business of providing end-to-end modular floating solutions. From engineering and designing to manufacturing and on-site installation, they're revolutionizing how clean energy can be installed on water. Their modular floating systems are constructed with UV-resistant HDPE, guaranteeing long-term durability, even in harsh weather conditions. Whether it's a small village lake or a large industrial reservoir, AIPL cuts each solution with precision.

AIPL doesn't only produce floats, though — they offer holistic services such as anchoring system design, grid integration support, and even maintenance after installation. They assist customers in complying with international solar standards and provide scalable export solutions. It's the complete approach that makes AIPL a go-to name in India's floating solar journey.

If you're questioning if floating solar is appropriate for your project — if you are a solar developer, government entity, or commercial enterprise — AIPL's group can assist in determining feasibility, tailoring modular platforms, and realizing your dream, literally afloat on the water.

At Acqua Infra Projects (AIPL), we go beyond manufacturing — we provide end-to-end solutions for floating solar deployment.

Q1. How long does a floating solar system last?

Floating solar systems last 25 to 30 years with good-quality materials and maintenance.

Q2. Can floating solar be placed on rivers?

It's ideally suited for slow-moving or still water bodies like lakes, ponds, and reservoirs to provide anchoring and stability.

Q3. Is floating solar more costly than land solar?

Though initial installation may be marginally more expensive, efficiency improvements, land conservation, and long-term returns usually pay for the difference.

Q4. How does AIPL make floating platforms long-lasting?

AIPL employs high-durability, UV-resistant lightware and durable Floating GFRC (Glass Fibre Reinforced Concrete) solar beams. Enhanced with EPS filling, these beams are virtually unsinkable and are specifically designed for mounting solar panels over water, offering exceptional durability with a claimed lifespan of up to 50 years. These Beams are built to meet project-specific certifications from NABL labs.

We collaborate with solar developers, government agencies, and energy companies to power progress on water.

In conclusion, floating solar isn't just a sustainable option; it's a smart, space-efficient, and scalable solution for a world striving to cut its carbon footprint. With industry players like AIPL, the sun shines brighter — even on water.

For more contact Us